Model 37255-Series

QUIET - FLUSH

ELECTRIC TOILET CONVERSION

FEATURES

• Very quiet flush cycle - like a household toilet

• Converts all Jabsco, Par manual toilets and early

electric toilets to the new Quiet-Flush System

• Also converts Groco HC, HE & HF; Raritan PH,

Cricket, Compact & Crown; Sealand (Mansfield) 750

to 752 series and all Wilcox Crittenden toilets

• Single button flush actuator - with dual function water

level control switch

• Supplied with Par-Max 4 self-priming pump to provide

sea water or lake water to rinse the toilet bowl

• High capacity waste macerator and bowl discharge

pump

SPECIFICATIONS

PORTS

PAR-MAX Pump and Toilet

Inlet 3/4" Hose Barb

Outlet 1" Hose Barb

MOTOR

Pump and Toilet meet U.S.C.G.

& SWITCH

Regulation 183.410 and ISO 8846

Marine for Ignition Protection.

EMC Models Available

WATER

1-2 Quarts (Litres)/Flush

CONSUMPTION

VARIATIONS

MODEL NO.

DESCRIPTION

37255-0012

Toilet Conversion, 12 Volt DC

37255-0092*

Toilet Conversion, 12 Volt EMC

37255-0024

Toilet Conversion, 24 Volt DC

37255-0094*

Toilet Conversion, 24 Volt EMC

*This model is Marked and complies with EN50081-1 for suppression of

electro-magnetic interference.

OPERATION

The Quiet-Flush Toilet Conversion provides both quiet

operation and user control of water levels in the toilet

bowl. A single large pushbutton switch provides a simple

flush mode by activating both the rinse water supply and

the macerator discharge pump simultaneously. An addi-

tional rocker switch offers independent control of the

rinse water supply and discharge pump separately so

the bowl water level can be easily raised or lowered by

the user. This provides a method of minimizing water

use, when desired, as well as a means of raising the

water level in the bowl when appropriate for user com-

fort. It also allows for complete evacuation of the bowl

water while underway in rough sea conditions.

INSTALLATION

The 37255-Series Quiet-Flush Toilet Conversion is com-

plete with a dedicated PAR-MAX 4 pump to provide either

sea or lake water to rinse the toilet bowl when flushing the

toilet. This pump is intended to be located remotely from

the toilet but will function best if the distance from the toi-

let is kept to a minimum. Because it is self-priming, it may

be located above the vessel’s waterline. It must be

installed with the Pumpgard strainer (provided with the

toilet) located somewhere in the inlet plumbing to the

pump. The toilet also includes a multi-function flush con-

trol which should be installed in a bulkhead location that

is convenient to the toilet and allows access for wiring to

run from the power source and to both the toilet dis-

charge pump and the PAR-MAX rinse water pump.

Before beginning the conversion, close all seacocks con-

nected with the toilet's plumbing system and take pre-

caution to ensure they remain closed until the conver-

sion is complete. If the toilet being converted is an elec-

tric toilet, disconnect the electrical power to the toilet and

take precaution to ensure it is not restored until the con-

version is complete.

Disconnect both inlet and discharge hoses from the old

toilet and remove the toilet from its mounting surface. If

the toilet being converted is an electric model, discon-

nect the electrical wiring from the toilet. Remove the

hose connected to the back of the toilet's china bowl and

remove the china bowl and seat & lid assembly from the

old toilet base assembly. Ensure the bottom surface of

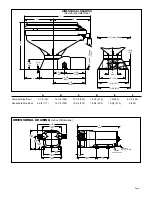

the china bowl is clean.The waste pump can be oriented

in any of the four possible mounting positions that pro-

vides the best clearance from surrounding obstructions

but is generally best positioned so it points to the rear of

the toilet bowl. The four 6 mm machine screws must be

Model 37255-Series