IS295-21C

J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com

Page 1/13

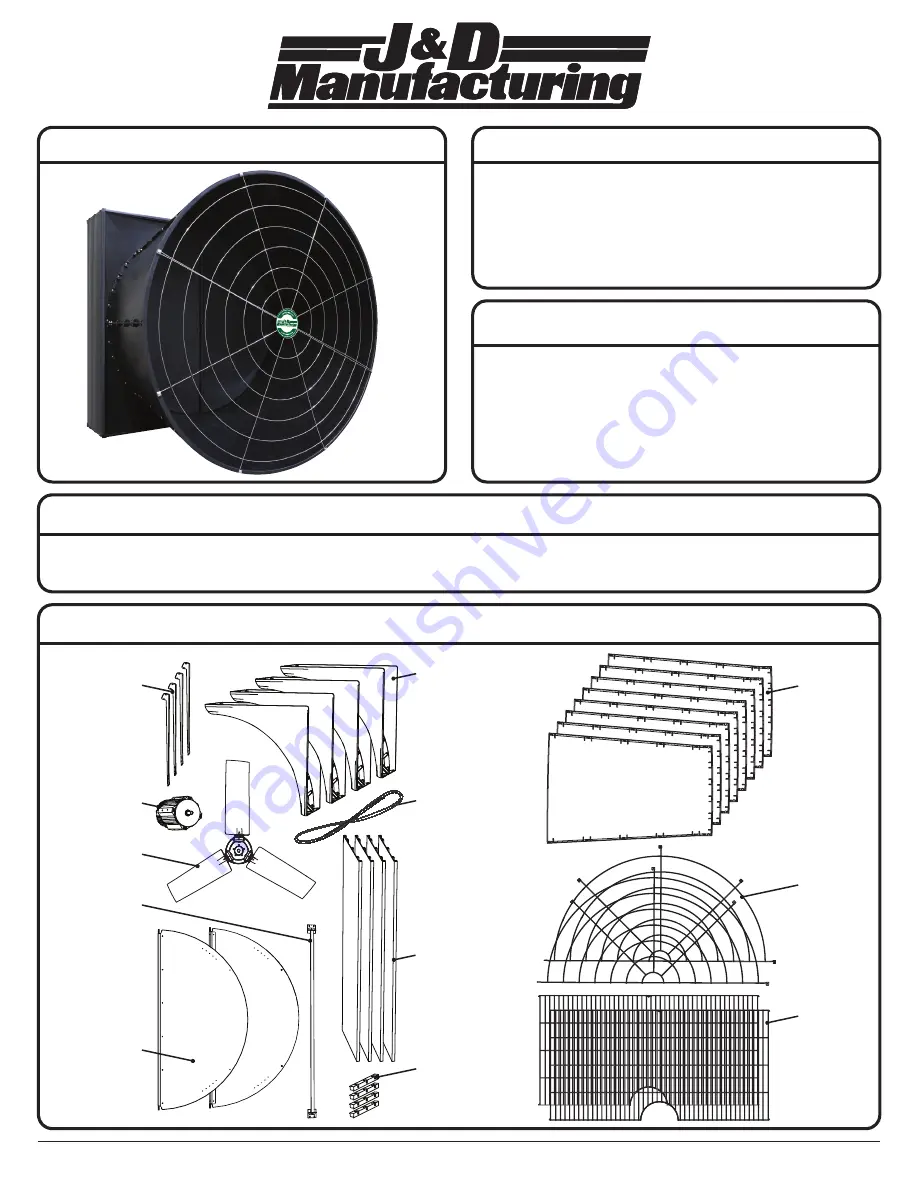

MAGNUM 58” EXHAUST FAN

J&D Mfg. warrants this products is free from defects in materials and workmanship under

normal use for the period of three years from date of purchase. Our warranty does not cover

ordinary wear and tear. J&D Mfg can repair or replace at our option, any product or part of

the product that is found to be defective. Our warranty applies to materials only and does not

include return freight, delivery, loss or damage to personal property, cost of removal or

installation, any incidental or consequential damages or labor. This warranty does not apply to

products which are misused, abused, altered, improperly installed or subject to negligence. All

warranties must be approved through our warranty department. The original purchaser must

present a copy of the invoice for the defective product.

Please read over ALL instructions carefully before you begin.

If you have any questions please call your local dealer, or contact J&D Manufacturing at 1-800-998-2398.

RECOMMENDED TOOLS & SUPPLIES FOR INSTALLATION

AND ASSEMBLY (NOT PROVIDED)

WARRANTY

INSTALLATION

(4) Venturi

Sections

Rubber

Gasket

(4) Motor

Brackets

Motor

Prop

Damper Door

Mounting

Bracket

Housing

Side Panels

(2) Damper

Doors

(4) Housing

Corner Caps

(8) Cone

Sections

(2) Front

Guards

(2) Rear

Guards

PARTS LEGEND

Back

Front

• Safety Glasses

• Socket Wrench

• 1/2” Socket

• 1/4” Nut Driver

• Impact Driver

• 1/2” Wrench

• 3/8” Wrench

• Drill

• 1/8” Drill Bit

• 13/64” Drill Bit

• 10 ft-lbs Torque Wrench

• 23 ft-lbs Torque Wrench

• Cutting Device

(for Rubber Gasket)

• Sealant (Minimal-Expanding

Foam / Polyurethane Caulk)