Page 1

Installation Instructions for 81540

MIG100 Gasless Welder

PLEASE READ MANUAL CAREFULLY BEFORE USING.

SAFETY INFORMATION

Before using welder, please ensure that you know:

1. Arc welding can be dangerous.

2. This welding machine must be connected to a power source in accordance with appliance electrical codes.

3. For safety turn off and unplug machine when installing new wire spool, adjusting wire tension roller or replacing

contact tip.

4.

The contact tip is electrically “hot” and if it contacts the grounded work piece it will cause damage.

5. All installation, maintenance, repair operation of this equipment should be performed by qualified technicians in

accordance with national, state and local codes.

6. Electric shock could kill.

7. Disconnect from power source before assembling, disassembly or maintenance of the torch or contact tip or

changing wire spools.

8. Fumes and welding gases can be dangerous.

9. Welding sparks can cause fire or explosion.

10. Arc rays can burn.

11. Hot metal will burn.

12. Electromagnetic fields may be dangerous.

WARNING!

PLEASE BE REMINDED TO WEAR ALL PROTECTION DEVICES BEFORE WELDING IN A SAFE PLACE.

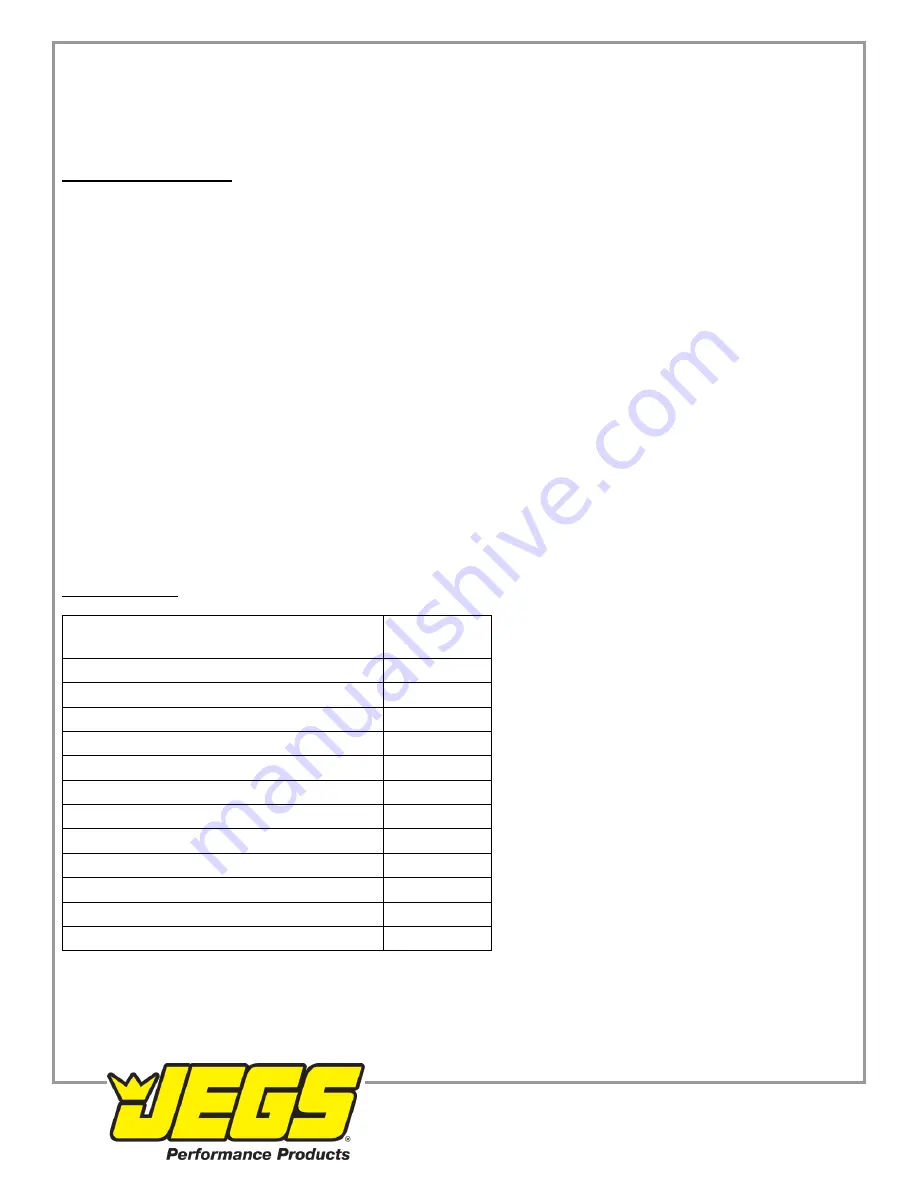

SPECIFICATION

Process(s)

Flux-Cored MIG

welding

GAS/FLUX

Flux

Input Voltage

110 V AC

Input Current

20 A

Input Frequency

60 Hz

Output Current Range

50-90A

Rated Duty Cycle

20% @90A

Open Circuit Voltage

27V AC

Wire Feed Speed

Infinite adjustable

Current Settings

4 Position

Flux cored welding wire dia.(inch)

0.03

’’-0.035’’

Insulation class

F

Protection class

IP21S

1-800-345-4545 jegs.com