16022089

March 2005

©

2005 Maytag Services

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

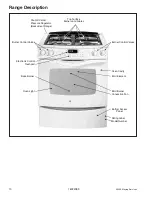

JGS8750ADB/S/W

JGS8850ADB/Q/S/W

Gas

Slide-In

Range

Summary of Contents for JGS8750ADB

Page 27: ... 2005 Maytag Services 16022089 A 1 Appendix A ...

Page 33: ... 2005 Maytag Services 16022089 B 1 Appendix B ...

Page 34: ...B 2 16022089 2005 Maytag Services Use Information ...

Page 35: ... 2005 Maytag Services 16022089 B 3 Use Information ...

Page 36: ...B 4 16022089 2005 Maytag Services Use Information ...

Page 37: ... 2005 Maytag Services 16022089 B 5 Use Information ...

Page 38: ...B 6 16022089 2005 Maytag Services Care Information ...

Page 39: ... 2005 Maytag Services 16022089 B 7 Care Information ...

Page 40: ...B 8 16022089 2005 Maytag Services Care Information ...

Page 41: ... 2005 Maytag Services 16022089 C 1 Appendix C ...