These appliances have been tested and certified by B G Technology for use with natural gas.

1.

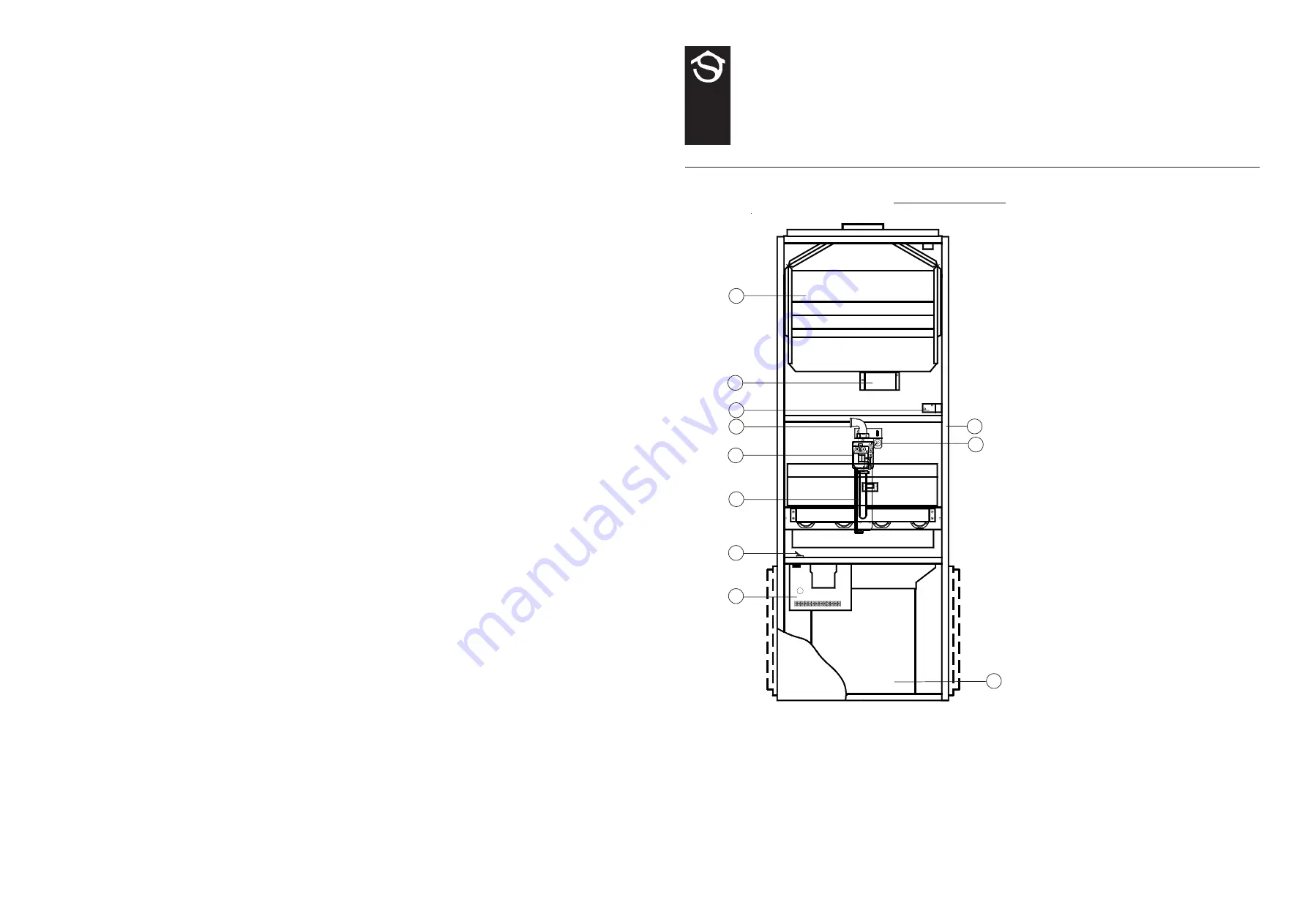

BRIEF DESCRIPTION

1

Air circulating fan

2

Control Panel

3

Data plate

4

Limit Switch

5

Multifunctional control

6

Burner and Control Assembly

7

Gas connection

8

Fan Delay Control

9

Piezo unit

10

Summer Air Circulation switch

11

Draught Diverter

JU SERIES WARM AIR HEATERS

INSTALLATION, COMMISSIONING & SERVICING INSTRUCTIONS

JU78: G.C. No 42 417 79

JU117: G.C. No 42 417 78

JU156: G.C. No 42 417 77

Publication No. ZZ 602/6

June 2003

These instructions are to be left with the User or adjacent to the Gas Meter

1

Fig. 1

General Layout Diagram

1.1

JU78, JU117 and JU156 are open-flued, fan assisted Upflow, ducted warm air heaters, the outputs of which are as

follows:

JU78:

23.0kW (82.8MJ/h, 78,500Btu/h)

JU117:

34.3kW (123.4MJ/h, 117,000Btu/h)

JU156:

45.7kW (164.5MJ/h, 156,000Btu/h)

THESE APPLIANCES CONFORM TO BS800

1

2

3

4

5

6

7

8

9

10

11

J

ohnson and Starley prides itself on its ability to supply spare parts quickly and efficiently. If you have a problem in obtaining a

spare part, please contact Johnson and Starley Spares Department at the address below.

JOHNSON & STARLEY LTD.

Telephone:

(01604) 762881

Rhosili Road,

Brackmills,

Fax:

(01604) 767408

Northampton NN4 7LZ