Ultra K17 — 16.8 K-factor

Upright Control Mode Specific Application Sprinkler

Standard Response, 155°F (68°C) & 200°F (93°C)

Page 1 of 4

AUGUST 2018

TFP330

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

General

Description

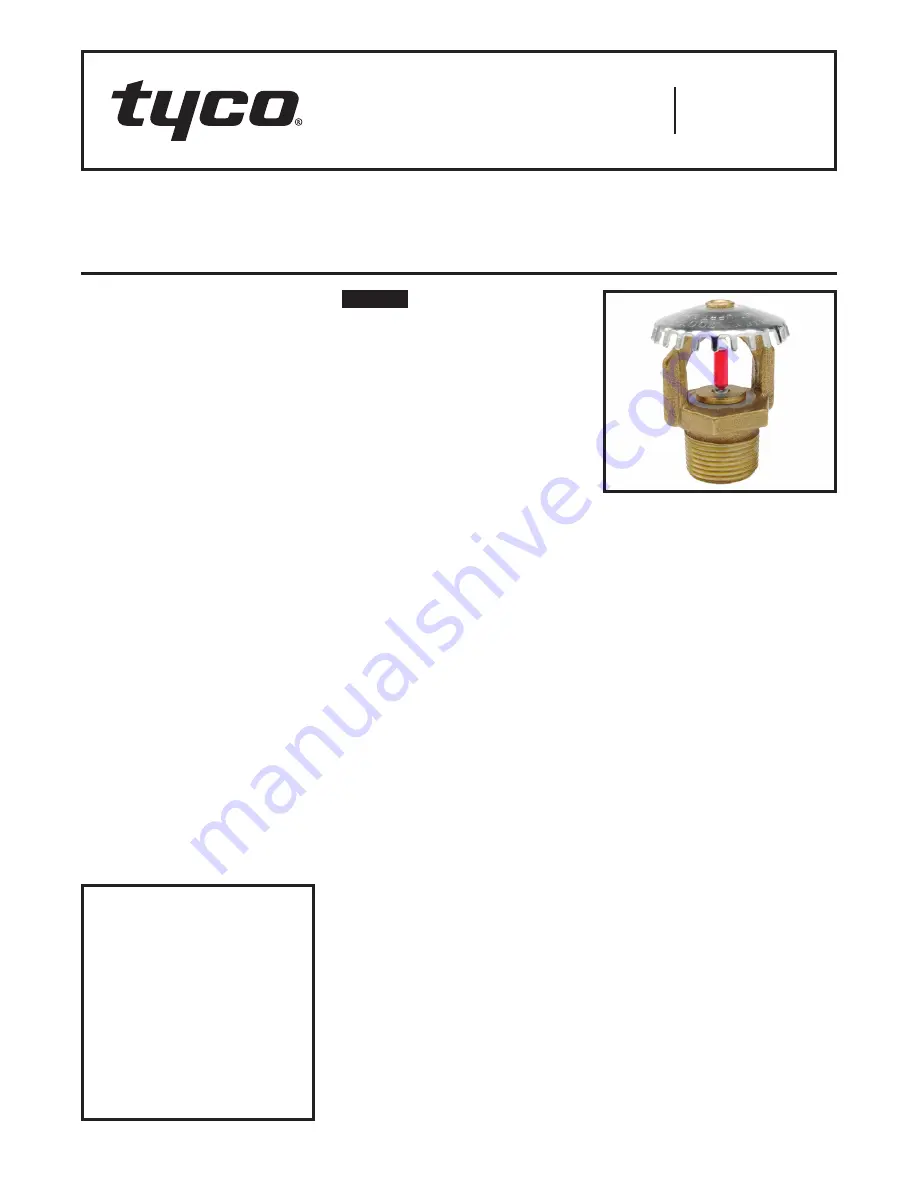

The TYCO 16.8 K-factor, Ultra K17,

Standard Response, Upright Control

Mode Specific Application Sprinkler

(Ref. Figure 1) is an automatic sprin-

kler of the frangible bulb type. It is

intended for use with National Fire Pro-

tection Association Control Mode Spe-

cific Application installation criteria for

the protection of high piled storage. It

may also be utilized as a 16.8 K-fac-

tor, upright, standard response storage

sprinkler in accordance with Factory

Mutual Loss Prevention Data Sheets.

See FM 2-0 and 8-9 for specific design

and installation criteria.

The Ultra K17 Sprinkler can provide a

higher level of protection than other

standard spray sprinklers and, in some

cases, it can provide an economi-

cal advantage by eliminating in-rack

sprinklers.

Applications for the Ultra K17 Upright

Control Mode Specific Application

Sprinkler are expanding beyond the

current specific application listings/

approvals. For information regard-

ing research fire tests which may be

acceptable to an authority having juris-

diction, please contact the Technical

Services Department.

NOTICE

The Ultra K17, Standard Response,

Upright Control Mode Specific Applica-

tion Sprinkler described herein must be

installed and maintained in compliance

with this document and with the appli-

cable standards of the National Fire

Protection Association, in addition to

the standards of any authorities having

jurisdiction. Failure to do so may impair

the performance of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Sprinkler

Identification

Number (SIN)

Refer to Table A for sprinkler identification

number.

Technical

Data

Approvals

UL and C-UL Listed

FM and NYC Approved

Refer to Table C for specific details on

laboratory listings and approvals. The

approvals apply to the service conditions

indicated in the Design Criteria section.

Finish

Natural Brass

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Sealing Assembly . .Beryllium Nickel w/TEFLON

Bulb (5 mm) . . . . . . . . . . . . . . . . . . . . . . . . .Glass

Compression Screw . . . . . . . . . . . . . . . . . .Brass

Deflector . . . . . . . . . . . . . . Chrome Plated Brass

Additional Technical Data

Refer to Table A for additional technical

data.

Operation

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and flow water.