MANUAL

#

OMP

L80

‐

P

REV.

6

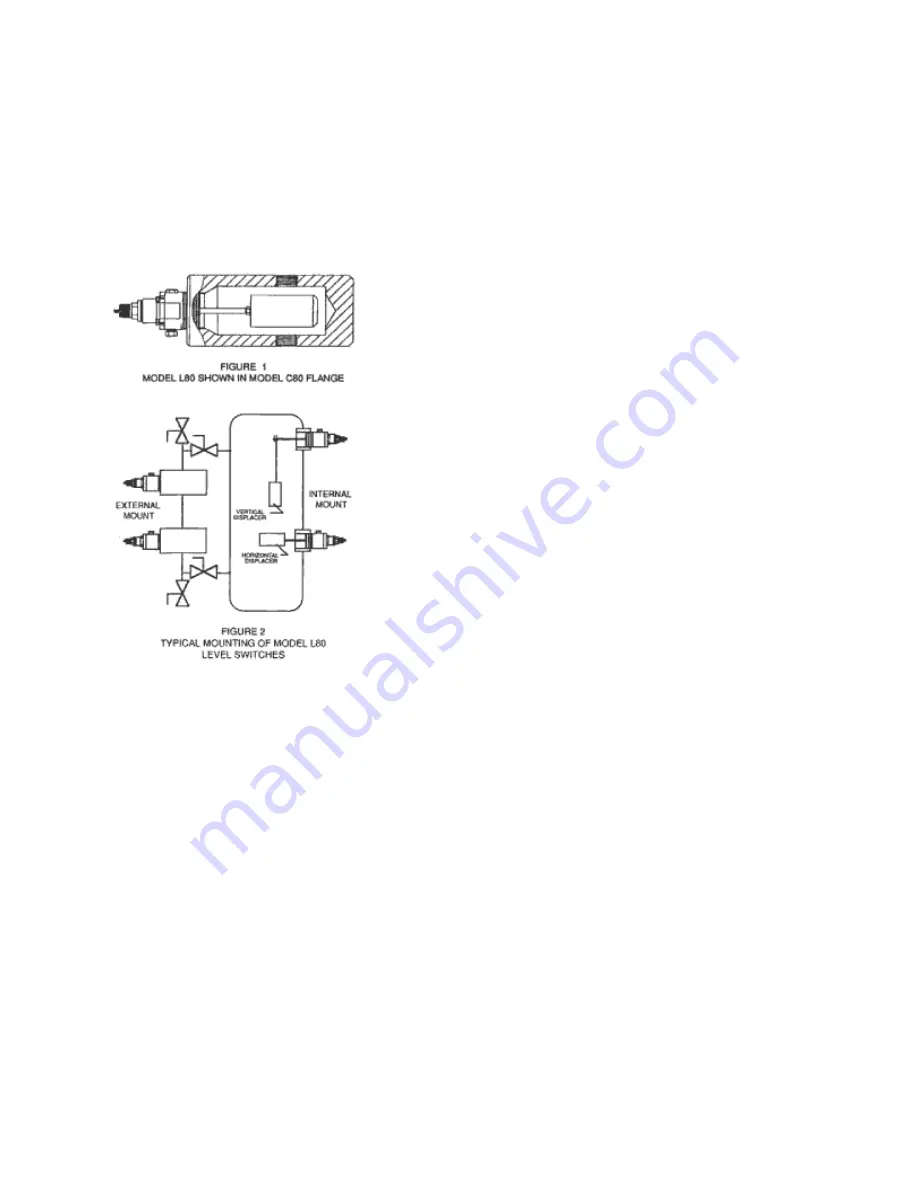

INTRODUCTION

The

K

‐

Dyne,

Inc.

electric

version

of

the

Model

L80

is

a

2"

NPT

mounted

liquid

level

switch.

It

is

typically

mounted

in

a

K

‐

Dyne

Model

C80

cage

shown

in

the

figure

1

for

external

bridle

mounting

or

may

be

internally

mounted

in

a

2"

NPT

(F)

connection.

Both

mounting

configurations

are

shown

in

figure

2.

These

sensors

send

or

remove

an

electric

signal

when

a

liquid

in

a

tank

or

a

pressurized

vessel

reaches

a

predetermined

level.

The

L80

operation

mode

as

either

a

low

(direct)

or

high

(reverse)

acting

level

switch

is

selected

by

rotating

the

pivot

body

180

˚

.

Selection

of

N.O.

or

N.C.

switching

depends

upon

the

wiring

configuration

utilized.

Both

SPDT

or

DPDT

snap

acting

dry

contacts

offered

with

the

switch

are

U.L.T

rated

for

hazardous

locations.

2.0

PRINCIPLE

OF

OPERATION

(Refer

to

Figure

3)

The

electric

version

of

the

K

‐

Dyne,

Inc.

Model

L80

2"

NPT

mounted

liquid

level

switch

is

a

multi

‐

functional

pneumatic

liquid

level

sensor.

Depending

on

the

mode

of

operation,

it

functions

as

a

three

way,

normal

closed

(N.C.)

or

normally

open

(N..O.)

electric

switch

that

will

operate

when

the

liquid

level

rises

or

falls

below

a

fixed

point

in

a

tank

or

pressurize

vessel.

Type

of

voltage

may

be

A.C.

or

D.

C.

and

the

maximum

amperage

depends

on

the

amount

of

voltage

used.

Consult

the

data

sheet

of

the

specific

switch

being

used

for

the

switch

rating.

The

switch

senses

a

change

in

the

buoyancy

of

a

displacer

assembly

(9)

inside

either

a

pressurized

or

an

unpressurized

vessel.

A

pivoting

action

is

used

to

transmit

the

buoyancy

change

of

the

displacer

assembly.

The

bore

of

the

cone

(14)

contacts

a

pivot

(13)

on

the

pivot

body

(3).

The

o

‐

ring

(8)

provides

a

pressure

tight

seal

between

he

body

(7)

and

the

shaft

of

the

cone

protruding

through

the

o

‐

ring.

Pressure

in

the

vessel

acting

on

the

shaft

of

the

cone

forces

the

cone

against

the

pivot.

The

position

of

the

pivot

point,

at

the

center

of

the

o

‐

ring,

allows

the

displacer

assembly

to

move

vertically

with

the

liquid

level.

This

motion

is

guided

to

act

along

the

axis

of

the

transverse

rod

(16)

by

two

vertical

tabs

on

the

pivot

body

that

mate

with

notches

in

the

cone.

Any

vertical

motion

of

the

displacer

is

transmitted

by

the

cone

to

the

ends

of

the

transverse

rod.

A

ramp

on

the

outside

diameter

of

the

transverse

rod

contacts

the

tip

of

the

push

rod

(17)

to

operate

the

lever

on

the

switch

assembly

(2).

2.1

LOW

OPERATION

For

use

as

a

low

‐

level

sensor

(output

on

rising

level),

the

pivot

body

(13)

is

positioned

with

the

enlarge

end

of

the

transverse

rod

(16)

up

towards

the

spring

cap

(4).

The

displacer

assembly

weight

exerts

a

clockwise

rotational

force

on

the

cone

through

the

pivot.

The

spring

(5),

acting

through

he

spring

guide

(6)

exerts

a

counterclockwise

rotational

force

on

the

cone.

When

the

liquid

level

is

below

the

displacer

assembly,

the

clockwise

force

is

greater.

This

force

causes

the

cone

to

push

upward

against

the

transverse

rod

allowing

the

tip

of

the

push

rod

to

be

positioned

away

from

the

switch

assembly

lever.

In