CHOICE OF DESCALING CHEMICAL AND

QUANTITY REQUIRED:

If the cooling coil is made of steel, or

stainless steel, use either SCALEBREAKER

SR or SCALEBREAKER FX, dependent on

the type of fouling. Scalebreaker FX will

remove both hard water deposits and

corrosion deposits, whilst Scalebreaker

SR is effective only on hard water scale.

SCALEBREAKER HD may be used with

copper coils, but should not be left in

circuit for more than two hours.

Do not use SCALEBREAKER HD with

stainless steel.

Calculate the amount of descaling

chemical required. As a guide, if

the volume of water in the cooling

circuit is approximately 100 litres,

use 10 litres descaling chemical (i.e. a

10% solution by volume). A weaker

solution may be used, but will take

longer to remove a given amount of

scale.

Heat may be applied into the coil, if

practicable, or it may be possible to

start descaling when the water in

the coil is still warm, to a maximum

of 50

o

C, and this will speed up

descaling.

NB. When descaling with any acid,

some hydrogen gas may be evolved.

Hydrogen is a flammable gas, and

the working area should be well

ventilated. Avoid smoking nearby,

or any other means of ignition.

PROCEDURE

1. Ensure an adequate water supply

to dilute or neutralise any chemical

leaks, or the spent descaling

chemical, so that disposal does not

contravene local regulations.

2. Isolate water inlet and outlet

connections to the cooling coil,

capping them off if necessary.

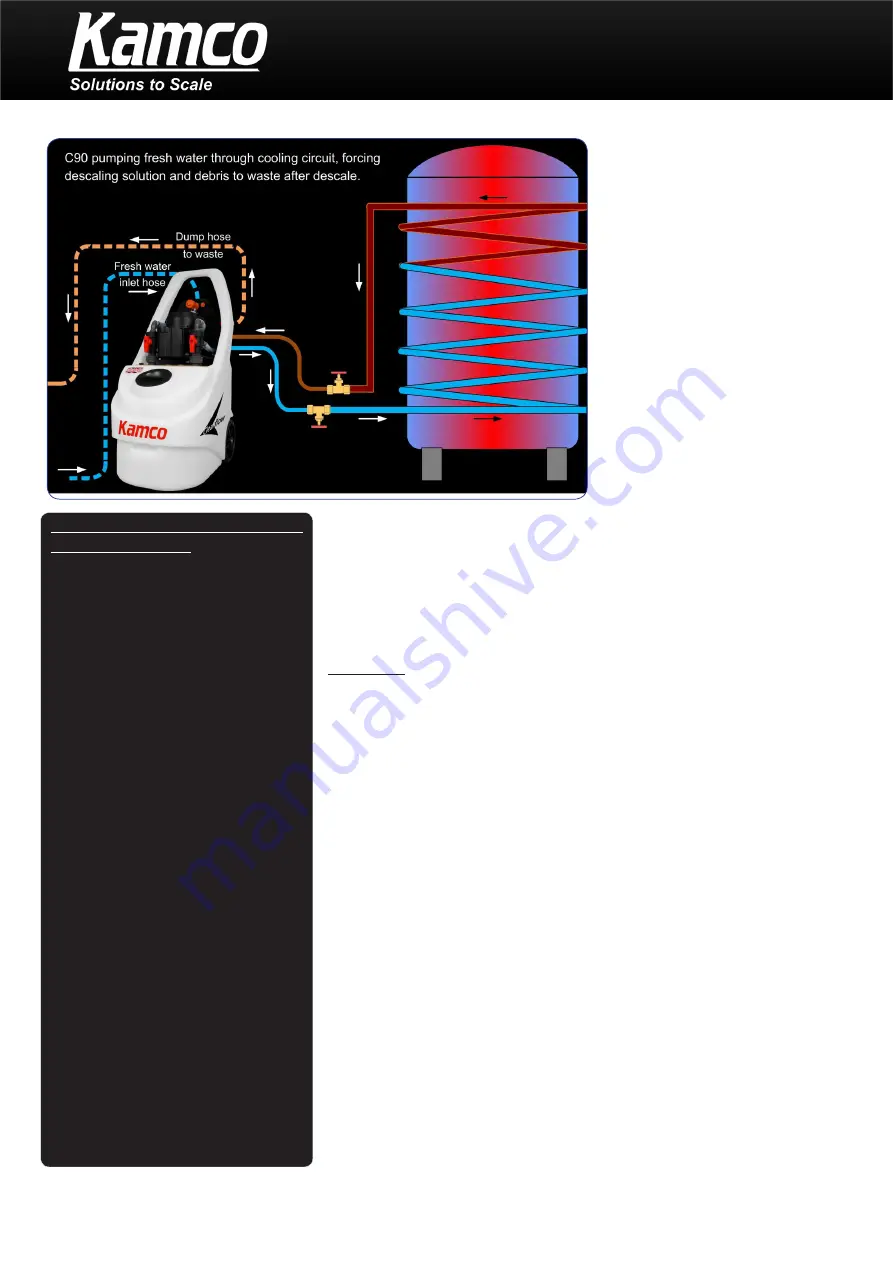

3. Couple flow and return hoses from

descaling pump to the water inlet

and outlet of the cooling coil to be

descaled.

4. If it is anticipated that descaling

is to be a routine maintenance

procedure, consider installing valved

tee-pieces in the flow and return

connections to the coil, terminating

in 1/2” or 3/4” BSP male threads. This

will enable immediate coupling of

the descaling pump across the coil

whenever descaling is required.

5. The pump connection to the lowest

connection onto the cooling coil

should be through a valve, as a

precaution. Failing this, if the

descaling pump is mounted below

the coil, power failure to the pump

would result in the head of water

overflowing the pump tank, unless

prevented by closing the valve.

(Scalebreaker FWF models have integral

valves suitable for this.)

6. Connections should be made so that

there is a closed circuit between

the pump output hose, through the

cooling coil to the return hose.

7. Venting of the carbon dioxide gas

evolved during descaling is achieved

through the pump tank filler cap

aperture. The cap should be screwed

on by no more than one quarter of

a turn. This is sufficient to vent the

gas, but at the same time reduces

fumes and prevents splashes.

8. Connect the pump to a suitable

earthed power supply. As the pump

will be used in a damp location, a

residual current circuit breaker plug

should be used.

9. The flow reverser handle points in

the direction of flow of the liquid. If

the handle points towards the hose

connected onto the normal water

inlet connection to the coil, that

will be the direction in which the

descaling pump will pump, and the

other hose will then be the return to

the pump tank.

10. Prior to adding descaling chemical

to pump tank, first ‘prove’ the circuit

with fresh water alone. Add water

to pump tank to approx. 4” (10cm)

above minimum liquid level, switch

on descaling pump, and immediately

Kamco Limited

Unit 9, Curo Park, Frogmore, St Albans. AL2 2DD. United Kingdom

Tel: +44 (0)1727 875020 Fax: +44 (o)1727 875335

E-mail: info@kamco.co.uk www.kamco.co.uk

Guidance notes on descaling cooling coils