Summary of Contents for 27-MD500

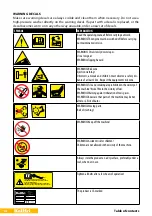

Page 11: ...11 Table of contents HK540G M D500 ...

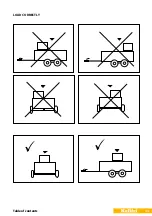

Page 13: ...13 Table of contents LOAD CORRECTLY ...

Page 32: ...32 Table of contents Item type L Stocked item B Order item ...

Page 34: ...34 Table of contents ...

Page 36: ...36 Table of contents ...

Page 38: ...38 Table of contents ...

Page 40: ...40 Table of contents ...

Page 42: ...42 Table of contents ...