INSTALLATION INSTRUCTIONS

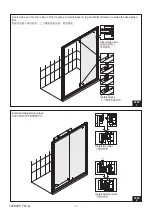

SLIDING, SCREEN, 1D1P, 8mm

8mm

K-705876T-FM-SHP

SLIDING, SCREEN, 1D1P, 10mm

10mm

K-81512T-FM-SHP

SKYLINE

-1-

BEFORE YOU BEGIN

BEFORE YOU BEGIN

·

·

·

·

·

·

3

(

)

80mm

3mm/m

·

QB 2584-2007

·

·

·

·

·

·

Before you install your shower door, please read

these instructions carefully to familiarize yourself

with the required tools, materials, and installation

sequences. Follow the sections that pertain to your

particular installation. This will help you avoid costly

mistakes. In addition to proper installation, read all

operating and safety instructions.

All information is based on the latest product

information available at the time of publication.

Kohler China Ltd. reserves the right to make

changes in product characteristics, packaging, or

availability at any time without notice.

These instructions contain important care, cleaning,

and warranty information-

Make sure that the bath and the finished wall

material are completely and correctly installed prior

to installing your shower door. Prepare waterproof

layer to wall and floor of the showering area. It is not

allowed for any presence of electric switches and

sockets. Make sure the floor drain runs smoothly.

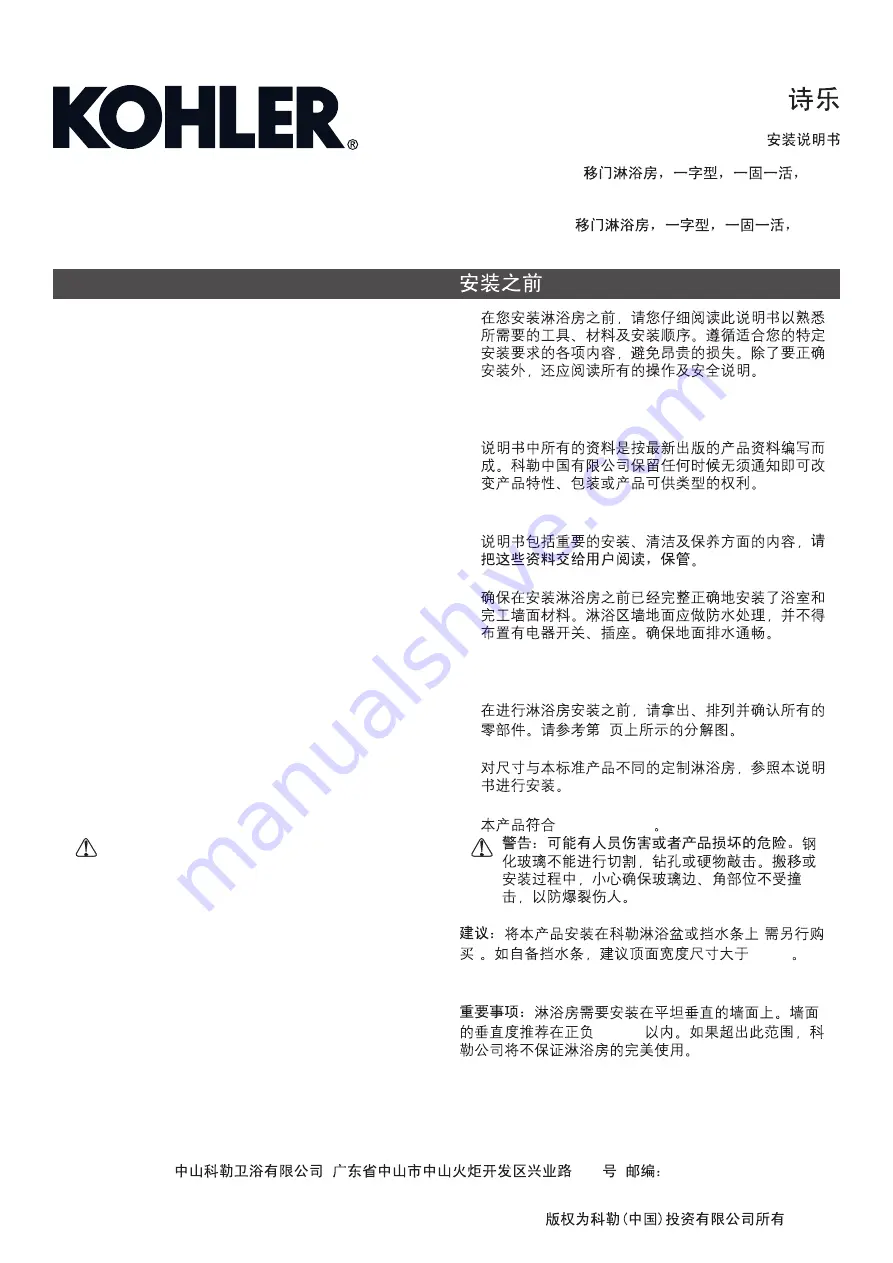

Before starting the door installation, lay out and

identify all the parts. Use the exploded view

illustrated on page 3 for reference.

For the installation method of customized shower

with different dimensions, please refer to this

instructions.

Tempered glass cannot be cut, drilled or

knocked by hard object. Make sure corner area

of the glass refraining from knocking so as to

cause personal injury due to broken glass.

Please install this door on Kohler

receptors or curbs(Not included). If the curb is not

Kohler-branded, please note its top width should be

more than 80mm.

The shower door requires a flat vertical

finished wall. The squareness of the wall is

recommended no more than 3 mm/m. KOHLER

Company won't take responsibility of the installation

quality.

please leave these

instructions for the consumer.

CAUTION: Risk of injury or product damage.

ATTENTION:

IMPORTANT:

·

The product complies with QB 2584-2007.

ZHONGSHAN KOHLER SHOWER CO., LTD.

NO13-1, XINYE ROAD, ZHONGSHAN TORCH

DEVELOPMENT ZONE, ZHONGSHAN, GUANGDONG, CHINA

POST CODE: 528437

13-1

528437

©

©

Copyright Kohler China Investment Co., Ltd. 2016

2016

1278975-T01-A