111864-2-

BA

(-)

Copyright

1996 Kohler Co.

WELLWORTH

LITE

VITREOUS CHINA

REVERSE TRAP TOILETS

BEFORE YOU BEGIN

HOW TO USE THESE INSTRUCTIONS

Please read these instructions carefully to familiarize

yourself with the required tools, materials, and installation

sequences. Follow the sections that pertain to your partic-

ular installation. This will aid you in avoiding the unneces-

sary expense associated with improper installation. In

addition to proper installation, read all operating and safe-

ty instructions.

All information in these instructions is based on the latest

product information available at the time of publication.

Kohler Co. reserves the right to make changes in product

characteristics, packaging, or availability at any time with-

out notice.

These instructions contain important care, cleaning, and

warranty information - please leave instructions for the

consumer.

NOTES

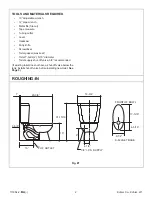

Seat post holes on 5-1/2” centers.

Water depth from rim is 6-11/16”.

1-3/4” passageway.

Ensure that the new toilet has the correct

roughing-in dimension. The K-3407 has a 10”

roughing-in dimension. See Fig. #1.

Be very careful while working with vitreous china

products. Vitreous china can break and chip if

you overtighten bolts and nuts or carelessly

handle the product.

Carefully inspect new fixture for any sign of

damage.

Observe all local plumbing and building codes.

Shut off hot and cold water supplies.

For new construction, refer to the dimensions in

Fig. #1 and Fig. #4 for locating the shut-off valve.

Fixture dimensions are nominal and conform to

tolerances by ANSI Standards (A112.19.2).

WARNING: Risk of external leakage. The fill

valve nut has been factory-tightened to design

specifications. If re-tightening is required, wrench

tighten one turn past finger tight.

ORDERING INFORMATION

Bowl K-4229

Tank K-4512

When specified:

3/8” supply

K-7638

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floor bolts (pr.)

21401

. . . . . . . . . . . . . . . . . . . . . . . . .

Recommended elongated seat

K-4652

. . . . . . . . . . .