Summary of Contents for u15-3

Page 1: ...WORKSHOP MANUAL KUBOTA EXCAVATOR U15 3 Code No 97899 61270...

Page 3: ...ss I Product engineering section II Service engineering section CONTENTS...

Page 4: ......

Page 6: ...WSM U15 3 I 2...

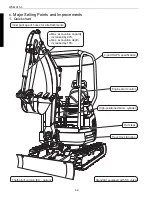

Page 20: ...WSM U15 3 I 16...

Page 65: ...WSM U15 3 II 45 b Performance curves...

Page 72: ...WSM U15 3 II 52 g Cooling system 1 Structure Hole Clamp Cap Through Cap pressure...

Page 83: ...WSM U15 3 II 63 3 Control Valve 2 Front Rear...

Page 88: ...WSM U15 3 II 68 7 Inner sectional view Tightening torque T 13 7 14 7 N m T 1 4 1 5 kgf m...

Page 130: ...WSM U15 3 II 110...

Page 132: ...WSM U15 3 II 112 n Hydraulic circuit diagram...

Page 170: ...WSM U15 3 II 150 8 Auto release and auto glow circuit combined Glow plug Glow lamp...

Page 200: ...WSM U15 3 II 180...

Page 209: ...ss Conversion Tables...

Page 210: ......

Page 211: ......