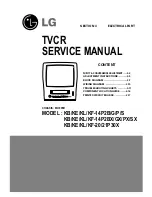

TVCR

SERVICE MANUAL

CAUTION

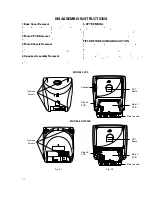

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MV-995B

MODEL : KB/KE/KL/KF-14P2B/G/P/S

MODEL :

KB/KE/KL/KF-14P2BX/GX/PX/SX

MODEL :

KB/KE/KL/KF-20/21P30X

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

SERVICE MANUAL

MODEL:KE/KL/KF-14P2BX/21P30X

LG Electronics inc.

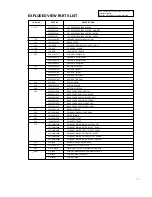

Summary of Contents for KB-14P2B

Page 22: ...3 7 BLOCK DIAGRAM ...

Page 23: ...VCD BLOCK DIAGRAM 3 8 ...

Page 24: ...VIDEO AUDIO BLOCK DIAGRAM 3 9 ...

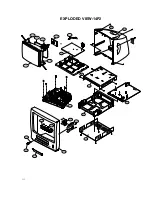

Page 32: ...3 17 PRINTED CIRCUIT BOARD MAIN ...

Page 33: ...3 18 POWER ...

Page 79: ...PB A REC A PB V REC V P No 3854VA0070A S Date 2001 02 10 CIRCUIT DIAGRAM OF MV 995B ...