- 1-1 -

[CONTENTS]

❍

SECTION 1. GENERAL

• SERVICING PRECAUTIONS ..................................................................................................... 1-2

• ESD PRECAUTIONS ................................................................................................................. 1-4

• SPECIFICATION ........................................................................................................................ 1-5

❍

SECTION 2. TROUBLESHOOTING

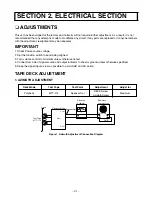

• ADJUSTMENTS ......................................................................................................................... 2-1

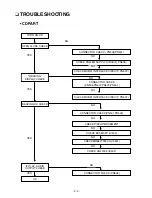

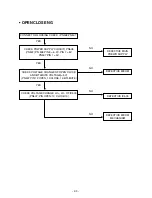

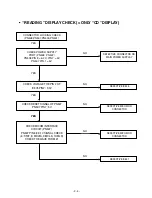

• TROUBLESHOOTING ............................................................................................................... 2-2

• WAVEFORMS OF MAJOR CHECK POINT ............................................................................. 2-11

• BLOCK DIAGRAM.................................................................................................................... 2-21

• SCHEMATIC DIAGRAMS ........................................................................................................ 2-23

• WIREING DIAGRAM ................................................................................................................ 2-31

• PRINTED CIRCUIT DIAGRAMS .............................................................................................. 2-33

• INTERNAL BLOCK DIAGRAM OF ICs .................................................................................... 2-42

❍

SECTION 3. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION ................................................................................... 3-1

• TAPE DECK MECHANISM: AUTOREVERSE DECK ................................................................. 3-3

• TAPE DECK MECHANISM: AUTOSTOP DECK(OPTIONAL) .................................................... 3-5

• CD MECHANISM ......................................................................................................................... 3-7

❍

SECTION 4. SPEAKER PART

• SPEAKER PART ........................................................................................................................ 4-1

❍

SECTION 5. REPLACEMENT PARTS LIST

• REPLACEMENT PARTS LIST .................................................................................................... 5-1

Summary of Contents for LX-M240 D

Page 5: ... SPECIFICATIONS 1 5 ...

Page 6: ... 1 6 MEMO ...

Page 27: ... 2 41 CD MAIN P C BOARD SOLDER SIDE ...

Page 28: ... 2 42 INTERNAL BLOCK DIAGRAM OF ICs KIA6225P S IC201 BIPOLAR LINEAR INTEGRATED CIRCUIT ...

Page 32: ... 2 46 MEMO ...

Page 34: ... 4 2 MEMO ...

Page 35: ...2 21 2 22 BLOCK DIAGRAM ...

Page 38: ... CDP SCHEMATIC DIAGRAM 2 27 2 28 ...

Page 39: ... EALA OAO SCHEMATIC DIAGRAM 2 29 2 30 ...

Page 40: ...2 31 2 32 WIRING DIAGRAM ...

Page 41: ... PRINTED CIRCUIT DIAGRAMS MAIN TUNER P C BOARD SOLDER SIDE 2 33 2 34 ...

Page 42: ...2 35 2 36 MAIN TUNER P C BOARD COMPONENT SIDE ...

Page 43: ...2 37 2 38 EALA OAO P C BOARD SOLDER SIDE EALA OAO P C BOARD COMPONENT SIDE ...