Approved for Hazardous Locations

Class I, Division 1, Groups C and D T4

Class I, Zone 1, Groups IIA and IIB T4

Installer: Manual must remain with owner or

operator/maintainer.

Prior to installation, record information

from pump nameplate for future reference:

Keep this manual handy for future reference.

For replacement manual, visit LibertyPumps.com,

or contact Liberty Pumps at 1-800-543-2550.

Retain dated sales receipt for warranty.

Model:

7000 Apple Tree Avenue

Bergen, NY 14416

ph: 1-800-543-2550

fax: 1-585-494-1839

www.LibertyPumps.com

Serial:

Mfg Date:

Install Date:

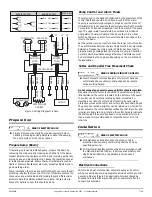

Installation

Manual

6850000D

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

Omnivore

®

Explosion-Proof

2 hp Grinder Pumps

XLSG and XLSGX-Series

Models

XLSG200-Series

Single-Stage

XLSGX200-Series

2-Stage High Head