Extruder Gear Replacement Guide for the M3D PRO

In this guide we will explain how to replace the extruder gear for your M3D PRO. You will need

a 2.0mm/1.5mm hex screwdriver for the disassembly and you’ll want to be in a antistatic

environment. Some electronics will be exposed during the disassembly and there is a chance

you could damage them. We recommend not working on a carpeted area and to discharge

before working. You can do this by touching something metal (Not the printer) for at least one

second. Wearing an antistatic wrist-wrap would be good. Link for a wrist-wrap here

Although, it is highly recommended to use an antistatic wrist-wrap, if you do not have access

to the antistatic wrist-wrap, you can do the repair process by having a metal contact to your

body throughout the repair.

Since the M3D PRO 3D printer is highly static device as there are various PCBs involved, if the

repair process is carried out without following the above recommendation and the customer

end up frying the electronics, they would need to send back their printers to M3D headquarters

for replacement.

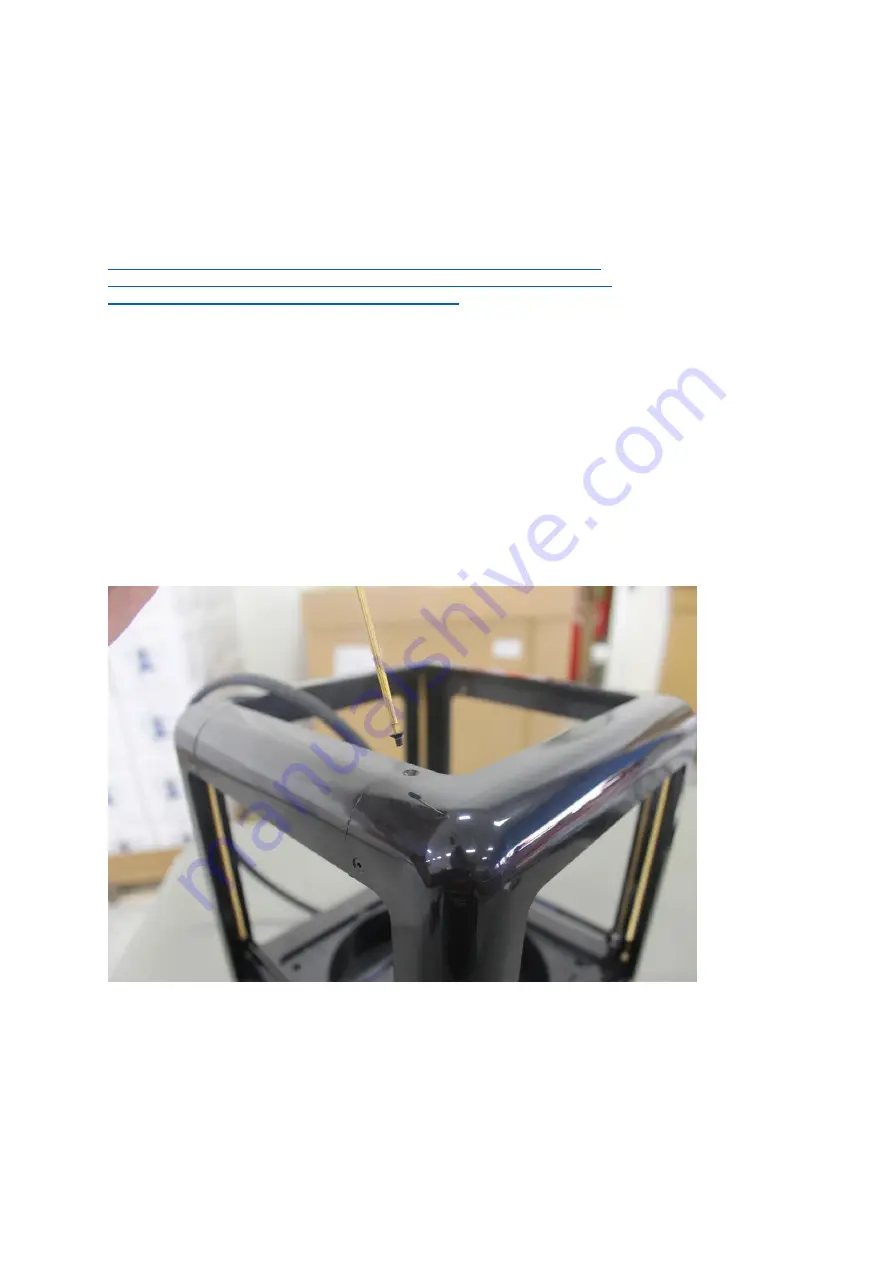

Step 1.

The first step will be to remove the front cover from the Pro. To do this you will need

to remove the hex screws from the cover. There are a total of 8 screws in each cover. Four

screws on the top and four screws on the bottom.

1.