1

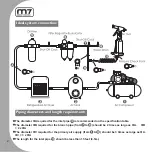

1. The maximum recommended air pressure during operation must not exceed 90 psi

(6.3bar). Higher air pressure may create unsafe operating conditions for the tool and

the user.

2. The compressed air should be cooled and have a water filter installed at the outlet

end of the compressor. Even with a water filter installed, some water may still

condense in the piping or hose and will enter the tool mechanism causing premature

damage to the tool. Therefore, it is recommended to install an air filter-lubricator

device somewhere between the tool and the compressor.

3. Always use an air compressor of the proper capacity to operate each tool.

4. Clean the hose with a blast of compressed air before connecting the hose to the air

tool. This will prevent both moisture and dust inside the hose from entering the tool

and causing possible rust or malfunction.

1. Using these tools in any potentially explosive environment is strictly prohibited.

2. It is always recommended that these types of tools must be operated when standing

on a solid or firm location.

3. Always use these tools in a well ventilated area.

4. Slipping, stumbling and falling are the major causes of potential serious injury,

therefore, a clean and clutter free surface in the working area before operating the

tools is strongly recommended.

Read this manual carefully before installing, operating,

servicing or repairing.

Working environment:

Air supply and connection requirements:

Summary of Contents for PA-111

Page 22: ...22 1 2 3 4 1 90 psi 6 3 2 3 4...

Page 23: ...23 1 2 3 4 5 6 7 8 9 10 11 12 13...

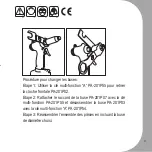

Page 24: ...24 1 2 3 4 5 6 PA 201 PA 201P03 P04 P05 PA 201P03A P04A P05A PA 201...

Page 30: ...30 1 2 3 4 1 90psi 2 3 4...

Page 31: ...31 1 2 3 4 5 6 7 8 9 10 11 12 13...

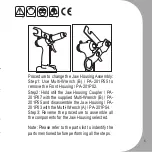

Page 33: ...33 1 P55 2 2 P55 2 P54 1A 3 P55 1 54 7 55 3 4 5 6 2 4 5 3 6 7 3 7...

Page 46: ...46 Air Hydraulic Riveter ltem No PA 111...

Page 48: ...48 Air Hydraulic Riveter ltem No PA 201...

Page 50: ...50 Air Hydraulic Riveter ltem No PA 201V...

Page 52: ...52 Air Hydraulic Riveter ltem No PA 211...

Page 54: ...54 Air Hydraulic Riveter ltem No PA 211TS...

Page 56: ...56 Air Hydraulic Riveter ltem No PA 301...

Page 58: ...58 Air Hydraulic Riveter ltem No PA 301V...

Page 60: ...60 Air Hydraulic Riveter ltem No PA 301MV...

Page 62: ...62 Air Hydraulic Riveter ltem No PA 321...

Page 64: ...64 Air Hydraulic Riveter ltem No PA 401V...

Page 66: ...66 Air Hydraulic Riveter ltem No PA 401MV...

Page 68: ...68 Air Hydraulic Riveter ltem No PB 2402...

Page 70: ...70...

Page 71: ...71...

Page 72: ......