Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

www.graco.com

Copyright 2003

Graco Inc. is registered to I.S. EN ISO 9001

309797P

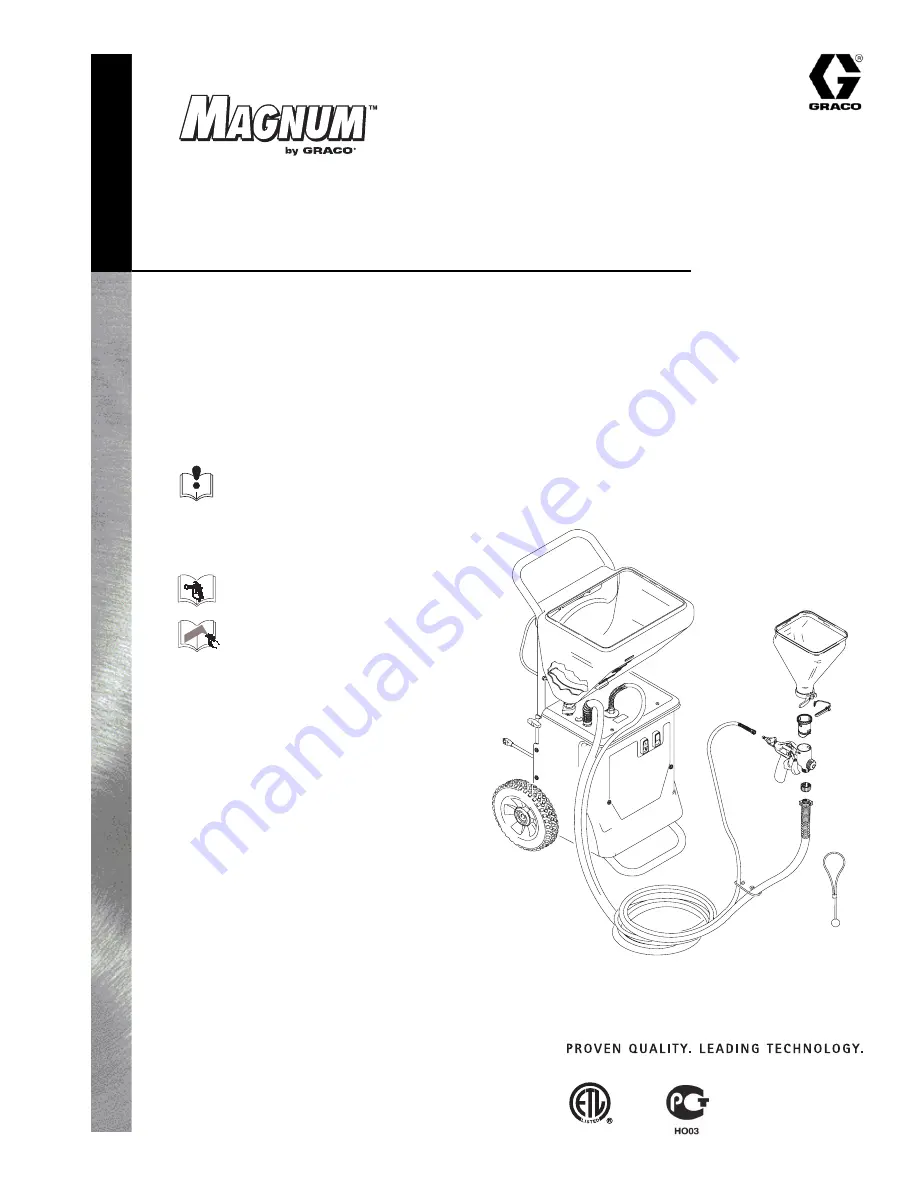

Repair

Interior Texture Sprayers

TexFinish™

U.S. patent D526,045

For Water-Based Materials Only

Models: 246185, 246186, 249175, 249176

55 psi (3.79 bar) Maximum Fluid Working Pressure

Related Manuals

Read warnings and instructions.

309584

309796

ti3157b

US

C

Conforms to ANSI/UL

standard 1450

Summary of Contents for TexFinish 246185

Page 20: ...Parts 20 309797P Parts E D WL H F F D 3DJH 81 ...

Page 22: ...22 309797P WL F 3DJH ...

Page 24: ...24 309797P ...