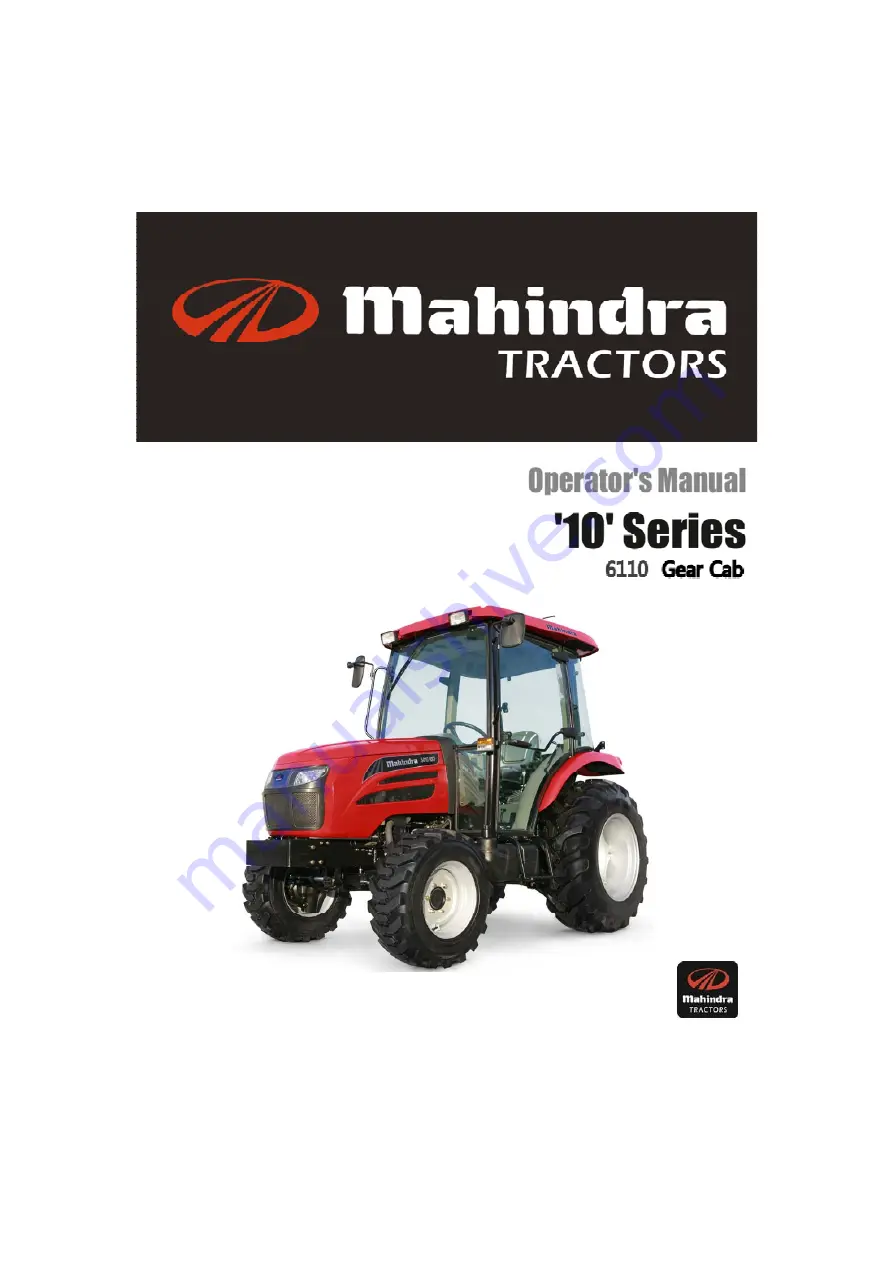

Summary of Contents for 10 Series

Page 1: ...Mahindra USA Inc 5203 Aeropark Drive Houston TX 77032 281 449 7771 www mahindrausa com...

Page 2: ......

Page 3: ......

Page 4: ......

Page 53: ...OPERATING THE 3 POINT LINKAGE TPL 49...

Page 108: ...6110 5010 Gear Cab TYPE WIRING DIAGRAM A3 104...

Page 109: ...6110 5010 Gear Cab ELECTRIC SYSTEM DIAGRAM 105...

Page 110: ...6110 5010 Gear Cab WIRING DIAGRAM 1 106...

Page 111: ...6110 5010 Gear CABIN WIRING DIAGRAM 2 107...

Page 112: ...6110 5010 Gear CABIN WIRING DIAGRAM 3 108...

Page 114: ...6110 Gear POWER TRAIN 110...

Page 116: ...DATE TRACTOR HOURS NATURE TYPE OF REPAIR SERVICE CARRIED OUT SERVICE RECORD 112...

Page 118: ...PART REPLACEMENT RECORD DATE PART DESCRIPTIO N Q TY COST DATE PART DESCRIPTION Q TY COST 114...

Page 119: ......