Models No.

Description

PRODUCT

C

ONCEPTION AND MAIN APPLICATIONS

S

pecification

S

tandard equipment

O

ptional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 / 17

T

ECHNICAL INFORMATION

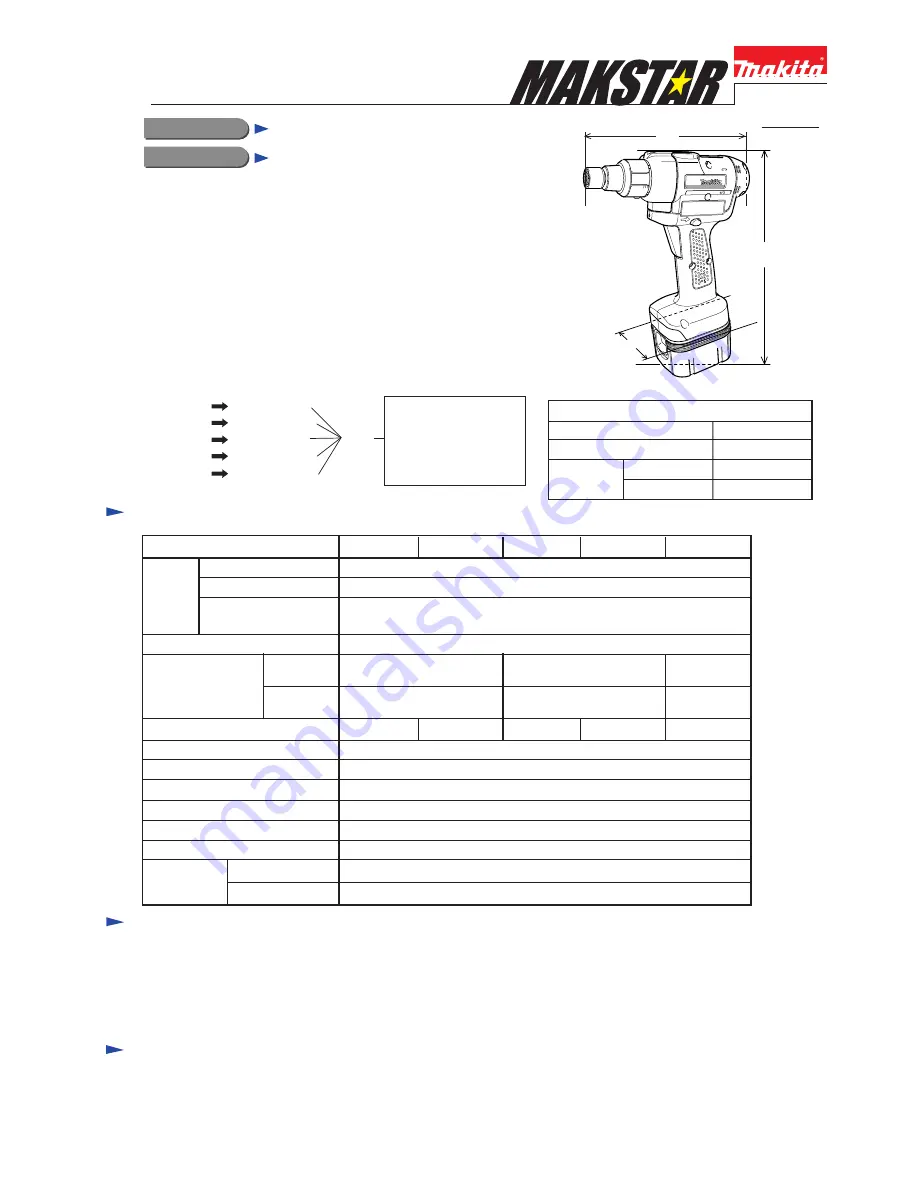

Dimensions (mm [inch])

Height (H)

Length (L)

190 [7-1/2]

266 [10-1/2]

With BH1220

With BH1233

289 [11-3/8]

Width (W)

71 [2-13/16]

BFH040, BFH040F, BFH090, BFH090F, BFH120F

12V Cordless Screwdrivers

The above cordless screwdriver series enable you to work

also in the hazardous location which is defined by

UL1604, Class I, Division 2.

The conformation to UL1604, Class I, Division 2 has been achieved by using

1. Brush-less DC motor for spark-free armature rotation.

2. Battery inter lock system

In addition to the above features, they have the following features.

* Soft start for suppressing starting shock

* Delayed restarter for avoiding unintentional over fastening

* Indication lamp, informing operator of the result of

fastening

* Battery BH1220 ...................................................... 2 pcs.

* Charger DC14SA .................................................... 1 pc.

* Torque adjust tool ................................................. 1 pc.

* Accessory case ........................................................ 1 pc.

* Steel carrying case .................................................... 1 pc.

* Battery BH1220

* Battery BH1233

* Charger DC14SA

* Charger DC24SA

* Adjust grip

* ADP 03 Automatic Refreshing Adapter

Model No.

No load speed : min

-1

= rpm

Fastening torque

: N.m

(in.lbs)

Battery

Electric brake

Driving shank

LED Job Light

Torque adjustment

Soft starter

Reverse switch

Over load protector

Net weight

: Kg (lbs)

Type of cell

Voltage : V

Capacity : Ah

Ni-MH

12

Hex 6.35mm (1/4")

2.0 Ah with battery BH1220

3.3 Ah with battery BH1233

400

1.5 (3.3)

1.8 (4.0)

Yes

Yes

Yes

Yes

Yes (Adjust grip is required.)

BFH040F

BFH040

BFH090

BFH090F

BFH120F

0.8 - 4.5

(7 - 40)

3.4 - 9.0

(30 - 80)

5 - 12

(44 - 106)

0.8 - 4.5

(7 - 40)

3.4 - 9.0

(30 - 80)

5 - 12

(44 - 106)

w/ 2.0Ah battery

w/ 3.3Ah battery

Hard joint

Soft joint

Yes

No

No

Yes

Yes

They come to market wit the following model name and the specification.

BFH040

BFH040SAE

BFH040F

BFH040FSAE

BFH090

BFH090SAE

BFH090F

BFH090FSAE

BFH120F

BFH120FSAE

* Battery 1220 x 2pcs.

* Charger DC14SA

* Torque adjsut grip

* Accessory case

* Steel carrying case

with

H

L

W