Models No.

Description

NEW TOOL

T

ECHNICAL INFORMATION

C

ONCEPT AND MAIN APPLICATIONS

S

tandard equipment

O

ptional accessories

P 1 / 13

O

ptional accessories

BFL300F, BFL400F, BFL401F

Cordless Angle Screwdriver 14.4V

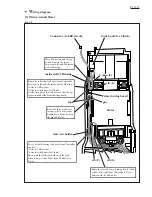

Models BFL300F and BFL400F have been developed

as specialist tools for industrial assembly applications,

featuring high torque capacity of 30N.m (BFL300F)/

40N.m (BFL400F).

Their brief advantages are;

*High precision fastening

*DC brushless motor for increased no load speed

*14.4V, 2.7Ah Ni-MH battery equipped with new type

battery cells for more efficient energy supply to motor

Model BFL401F is a sister tool designed for Italy.

These models do not include battery and charger.

BFL300F

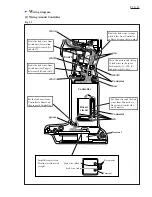

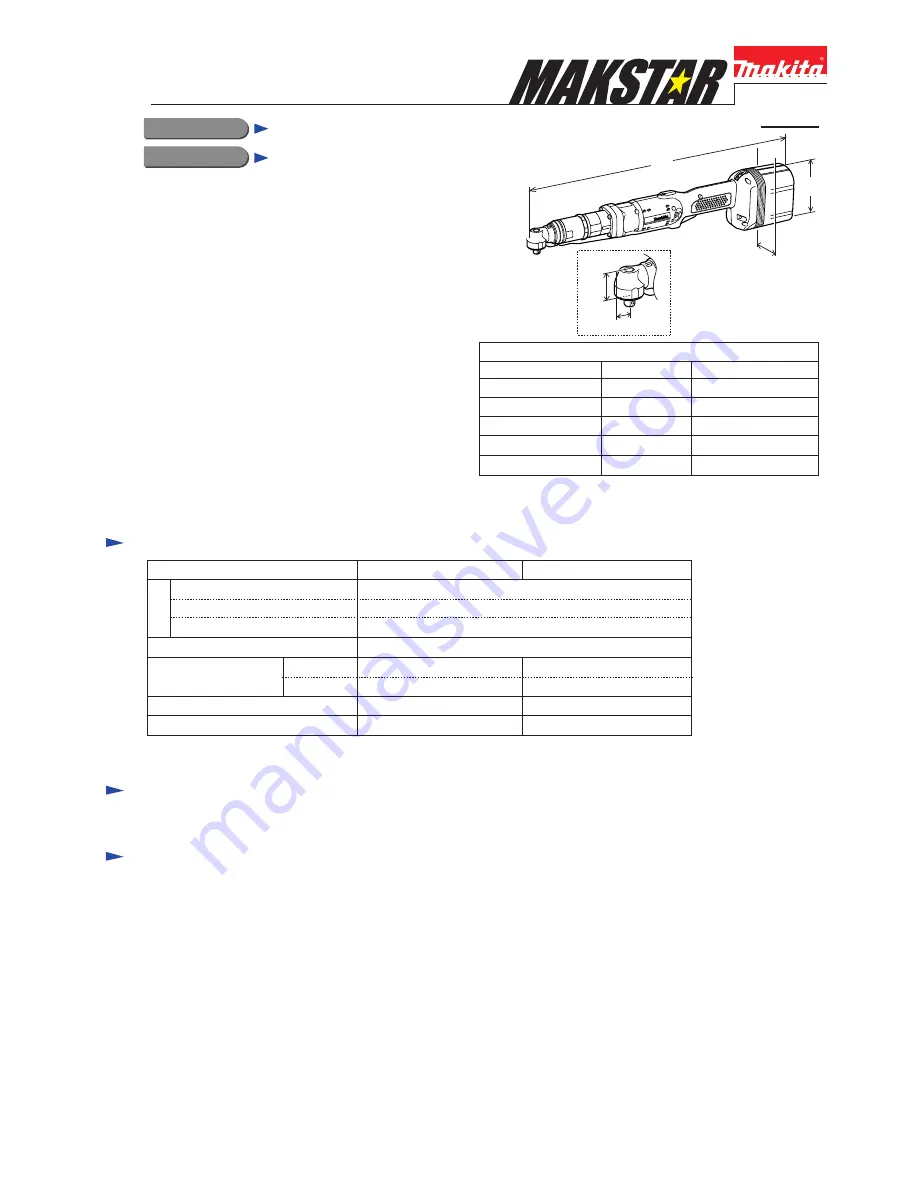

Dimensions: mm (")

Model No.

Length (L)

Height (H)

Width (W)

BFL400F/ BFL401F

506 (20)

510 (20-1/16)

104 (4-1/8)

73 (2-7/8)

104 (4-1/8)

73 (2-7/8)

Center height (CH)

Head height (HH)

16 (5/8)

31.5 (1-1/4)

18 (11/16)

34 (1-5/16)

W

H

L

S

pecification

BFL400F/ BFL401F

Model No.

No (however, with Protector for some countries, and with Torque adjust tool for some countries)

Ni-MH battery BH1427

Chargers DC24SA, DC14SA, DC14SC

Automatic refreshing adapter ADP03

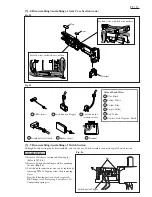

Switch lever set (paddle switch)

Spindle G complete (12.7mm square drive)

Protectors Red, Blue, Yellow, Clear

Torque adjust tool

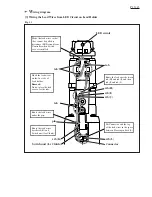

No load speed: min.-

1

=rpm

Fastening torque: N.m

Voltage: V

Capacity: Ah

Cell

Net weight: kg (lbs)

*Note: 12.7mm (1/2") with optional Spindle G complete

Hard joint

Soft joint

Battery

2.7

14.4

Ni-MH

Capacity

9.5mm (3/8") Square drive*

400

260

16 - 30

25 - 40

16 - 30

25 - 40

2.3 (5.1)

2.4 (5.3)

BFL300F

* Paddle lever

* Protector

HH

CH

*Battery is optional.