PRODUCT

P 1/ 14

Model No.

Description

GA4041, GA4541, GA5041, GA6041

Angle Grinders 100mm (4"), 115mm (4-1/2"),

125mm (5"), 150mm (6")

1,100W Angle grinder series models; GA4041, GA4541, GA5041 and

GA6041 are successor models of 9560 series models, featuring:

•

"

Super Joint System II

"

developed for effective vibration absorption

•

Mechanical brake

for powerful braking

• Re-designed durable gear housing

• Ergonomically best possible barrel grip

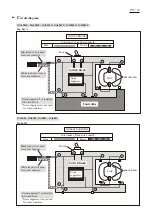

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

Model No.

325 (12-3/4)

GA4041, GA4541,

GA5041, GA6041

117 (4-5/8), 130 (5-1/8),

140 (5-1/2), 171 (6-3/4)

117 (4-5/8), 121 (4-3/4),

121 (4-3/4), 121 (4-3/4)

L

H

W

S

tandard equipment

Note:

The standard equipment for the tool shown above may vary by country.

Side grip .......................................1

Lock nut wrench ..........................1

Depressed center wheel ................1 (100mm for GA4041, 115mm for GA4541, 125mm for GA5041, 150mm for GA6041)

O

ptional accessories

Depressed center wheels

Rubber pads

Dust collection wheel guards

Abrasive discs

Wire cup brush sets

Wheel covers for wire cup brush sets

Wire bevel brush sets

Wheel covers for wire bevel brush sets

Diamond wheels

Dust collecting wheel guards

Abrasive cut off wheels

Wheel covers

Sanding lock nut

etc.

S

pecification

Continuous Rating (W)

Voltage (V)

Cycle (Hz)

Input

Output

700

Max. Output (W)

110

120

220

230

240

11

10

5.3

5

4.8

50/60

50/60

50/60

50/60

50/60

1,100

1,100

1,100

1,100

1,100

1,300

1,300

1,300

1,300

1,300

Current (A)

700

127

9.1

50/60

---

1,300

700

700

700

700

*1

With Side grip, Wheel cover, Inner flange, Lock nut

Model No.

No load speed: min.

ˉ

¹=rpm

Diameter

Hole diameter

Wheel size:

mm (")

Protection against electric shock

Power supply cord: m (ft)

Weight according to

EPTA-Procedure 01/2003

*

1

: kg (")

GA4041

GA6041

100 (4)

115 (4-1/2)

European countries except UK: 4.0 (13.2), Brazil, Australia: 2.0 (6.6)

Other countries: 2.5 (8.2)

11,000

150 (6)

Double insulation

22.23 (7/8)

16 (5/8)

Max. thickness

6 (1/4)

Shock absorbing System

Mechanical brake

Super Joint System II

No

No

No

No

Constant speed control

Variable speed control by dial

Soft start

Electronic current limiter

Anti-restart function

Electronic

control

No

Yes

GA4541

125 (5)

2.5 (5.5)

2.6 (5.8)

2.7 (6.0)

GA5041

9,000

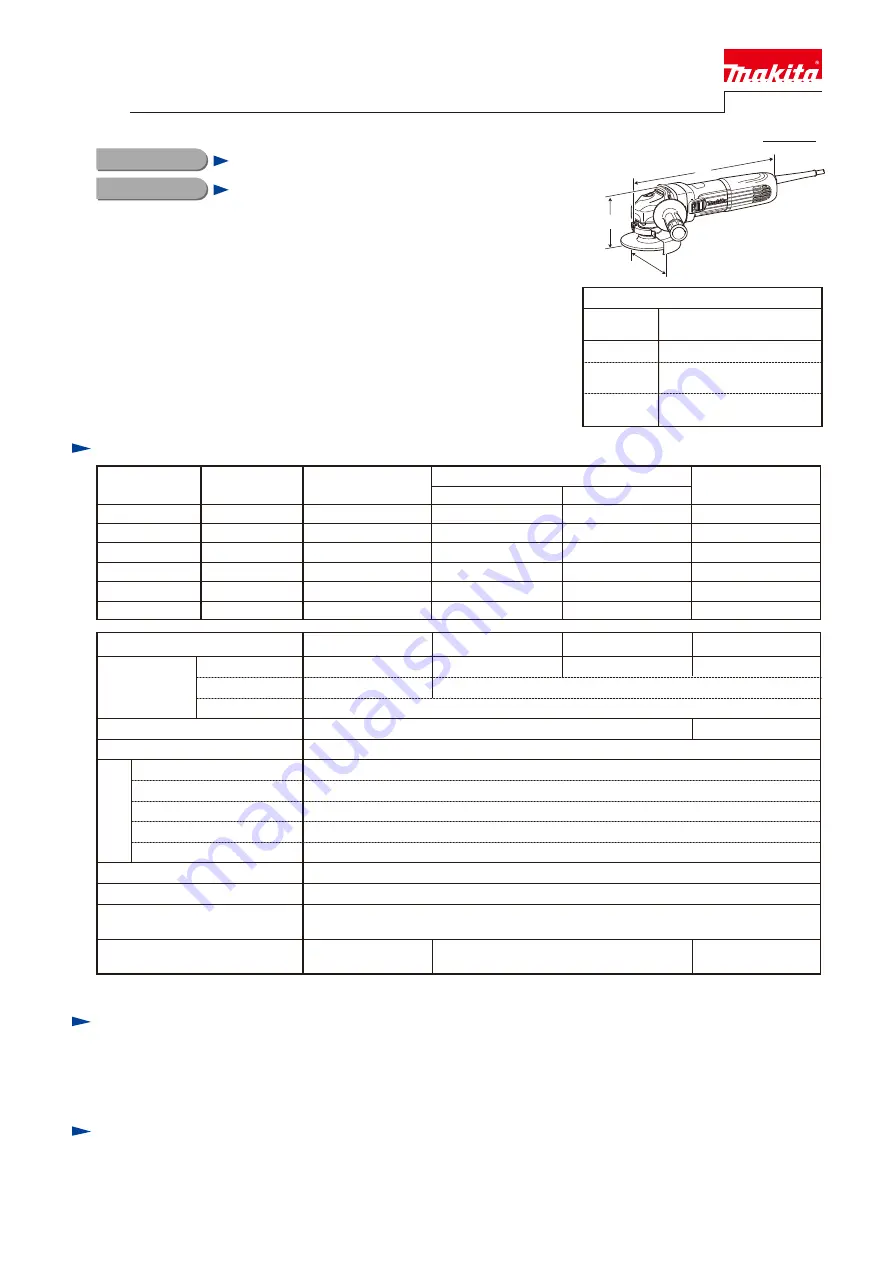

T

ECHNICAL INFORMATION

C

ONCEPT AND MAIN APPLICATIONS