P 1/ 10

PRODUCT

C

ONCEPT AND MAIN APPLICATIONS

S

pecification

S

tandard equipment

O

ptional accessories

Note:

The standard equipment for the tool shown above may vary by country.

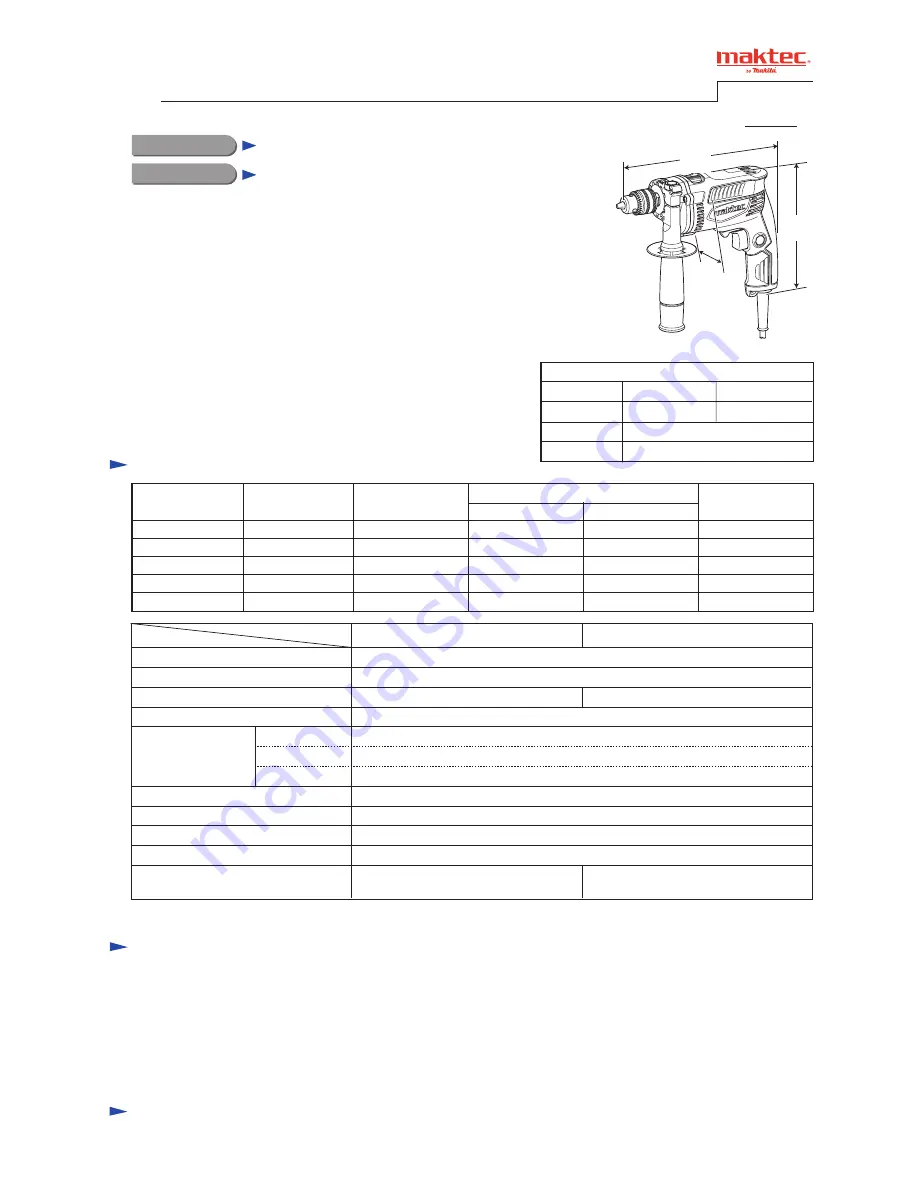

Model No.

Description

MT817, MT818

Hammer Drills 13mm (1/2")

Models MT817 and MT818 have been developed as the cosmetic

change of

maktec

hammer drills MT811 and MT812.

Their main features are:

• Industrial performance and durability at less expense

• Ergonomically designed handle with rubberized soft grip

The specification difference between these models are:

MT817/ 13mm (1/2") hammer drill with Keyed chuck

MT818/ 13mm (1/2") hammer drill with Keyless chuck

These models are also available with plastic carrying case

as “K” models; MT817K, MT818K

No

110

120

230

240

4.1

50/60

50/60

50/60

50/60

3.8

2.0

1.9

430

---

430

430

220

220

220

220

340

340

340

220

50/60

2.1

430

220

340

340

Continuous Rating (W)

Voltage (V)

Cycle (Hz)

Input

Output

Max. Output (W)

Current (A)

Dimensions: mm ( " )

Width (W)

Height (H)

Length (L)

Model No.

(The image above is MT817.)

MT817

MT818

255 (10)

258 (10-1/8)

193 (7-5/8)

72 (2-13/16)

Chuck capacity: mm (")

Chuck type

Reverse switch

Impacts per min.: min.

ˉ

¹= ipm

Capacities: mm (")

Steel

Concrete

Wood

Protection against electric shock

Power supply cord: m (ft)

Weight according to

EPTA-Procedure 01/2003

*

: kg (lbs)

0 - 2,800

Model No.

MT817

0 - 30,800

Keyed

1.5 - 13 (1/16 - 1/2)

13 (1/2)

13 (1/2)

18 (11/16)

Yes

Double insulation

1.8 (3.9)

2.0 (6.6)

MT818

Keyless

1.7 (3.7)

Variable speed control by trigger

Yes

*

with Side grip

Chuck key S-13 ................................................ 1 (MT817 only)

Key holder 10 ................................................... 1 (MT817 only)

Side grip ........................................................... 1

Depth gauge ..................................................... 1 (for some countries)

Cap ................................................................... 1 (for some countries)

Plastic carrying case ........................................ 1 ("K models" only)

No load speed: min.

ˉ

¹=rpm

Specification

T

ECHNICAL INFORMATION

H

W

L