Reviews:

No comments

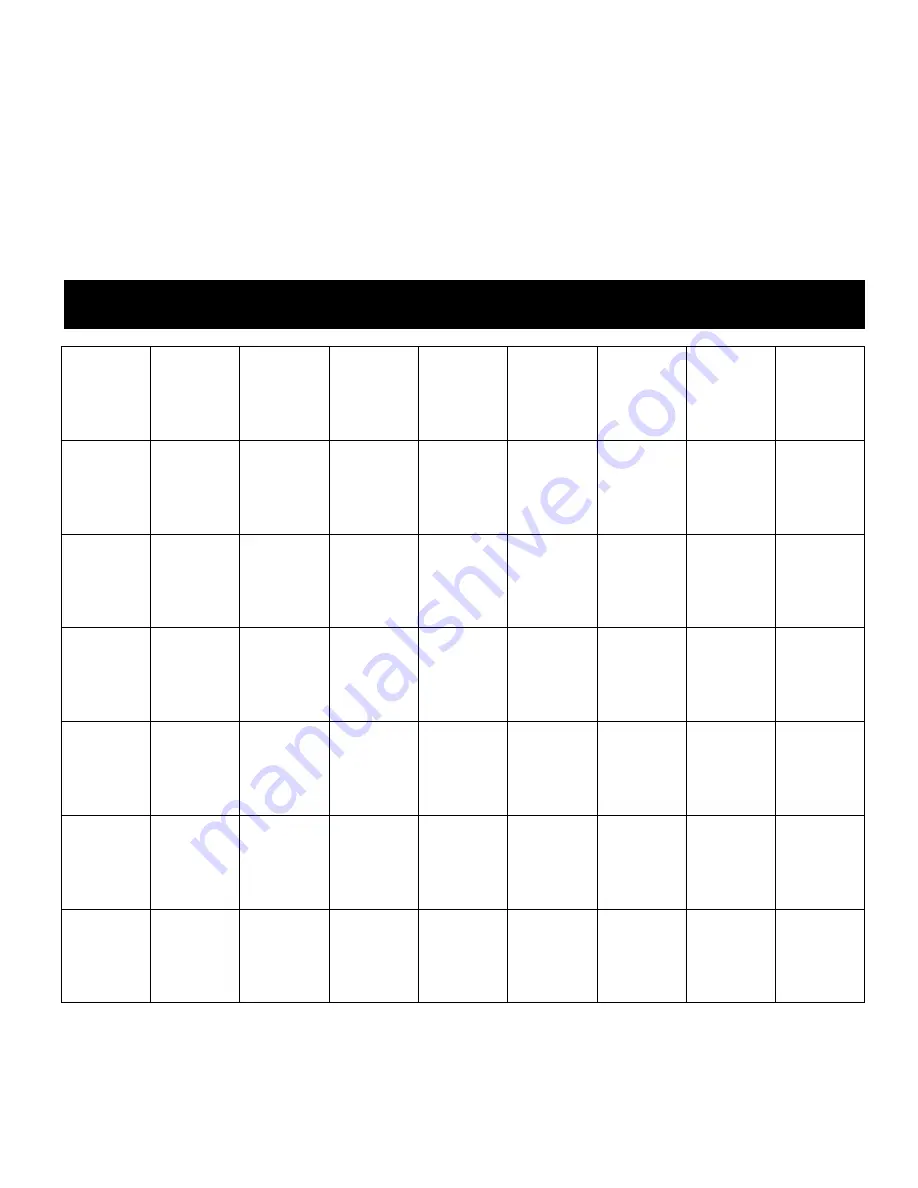

Related manuals for BSA-950LM

814

Brand: Gardena Pages: 4

DAPSP5L

Brand: Daewoo Pages: 14

DAMSP16L

Brand: Daewoo Pages: 18

ABK-PRO

Brand: Ozito Pages: 7

spray gun

Brand: Powermate Pages: 41

250 BAR / 3627 PSI

Brand: Kremlin-Rexson Pages: 2

6655

Brand: BGS technic Pages: 17

POLMAX

Brand: MATABI Pages: 6

ULTRA MAX 795

Brand: Graco Pages: 36

MS-40

Brand: Echo Pages: 8

0520753

Brand: WAGNER Pages: 12

SPRAY STATION HV 2900

Brand: Earlex Pages: 40

DM-6110

Brand: Echo Pages: 68

ATM1040

Brand: Ferm Pages: 24

SGM1008

Brand: Ferm Pages: 96

SGM1011

Brand: Ferm Pages: 140

17M363

Brand: DeWalt Pages: 11

V 20 664

Brand: WALTHER PILOT Pages: 49