4.1.16

11/2004

Marvin Service Manual

11708609

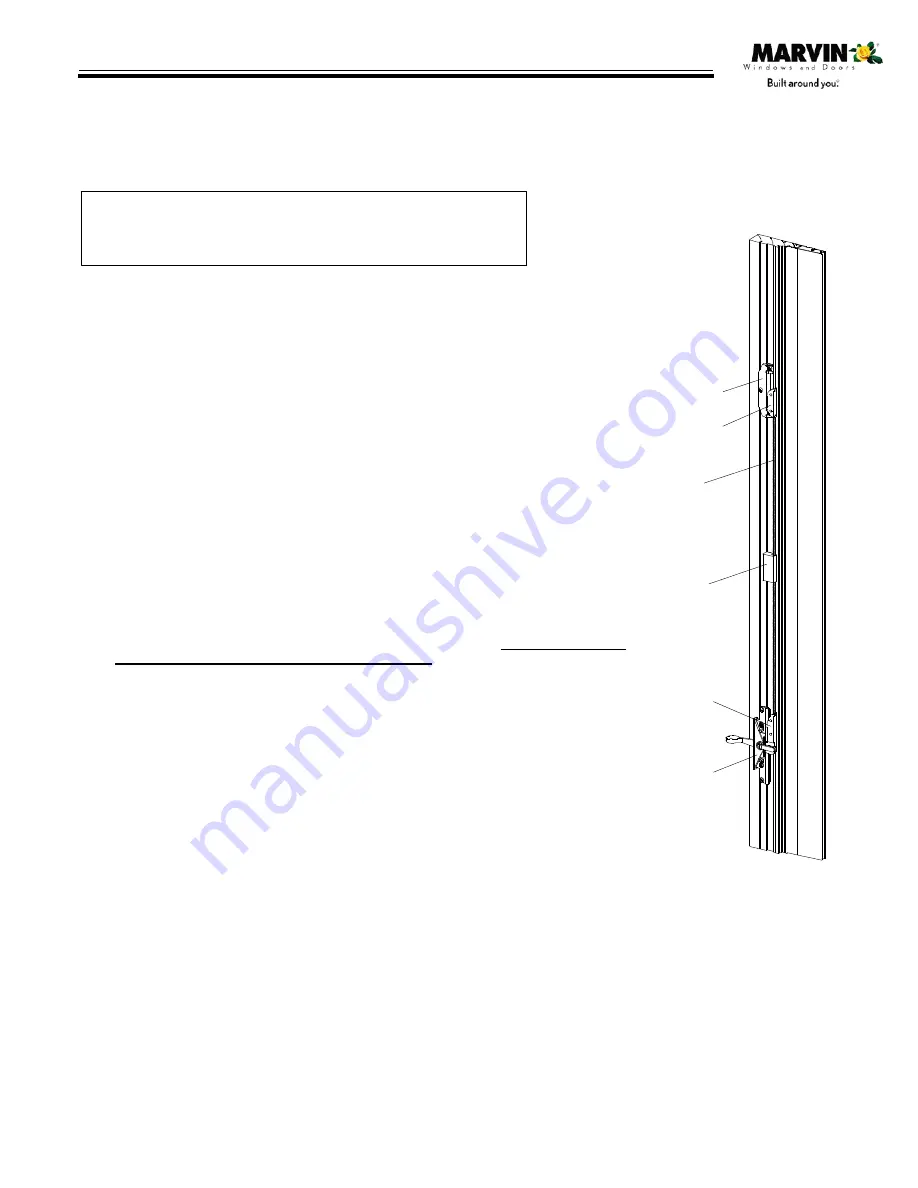

Secondary

Lock

Secondary

Lock Cam

Tie Bar

Support

Block

Primary

Lock Cam

Primary

Lock

Clad units manufactured after January 31, 1994

Wood units manufactured after February 7, 1994

Phillips screwdriver

Hammer

Safety glasses

Stiff putty knife (blade must be sharp and square on end)

Small wood block (approximately 1

″

x 2

″

x 6

″

)

REMOVING SEQUENTIAL LOCKING SYSTEM

1. Unlock and open window.

NOTE: If sequential lock fails to operate and window cannot be opened, complete steps

3 and 4 to remove stops and follow these steps:

A.

Starting near the head jamb carefully insert the putty knife between the lock side stop

and jamb. Gently pry the side stop away from the jamb so the locking mechanism is

visible. Insert the wood block to hold the side stop away from the jamb.

B.

Place the putty knife on the top of the primary cam and tap downward with a hammer

until the cam disengages from the keeper(s). Open window.

2. Remove roto--gear folding handle and cover. Remove screen.

3. Remove hardware cover by inserting putty knife between cover and sill. Gently lift

hardware cover from sill.

4. Remove head jamb stop by inserting putty knife between stop and head jamb. Gently pry

stop downward until it can be removed.

NOTE: If plastic barb stays in kerf during either step, simply push it back into place by hand until

fully seated.

5. Remove the locking side jamb weatherstrip by carefully inserting the putty knife between

the side stop and the weatherstrip, prying the weatherstrip out.

6. Pull back the head jamb and sill weatherstrip to the hinge track, it is not necessary to

completely remove the head jamb or sill weatherstrip.

7. Starting near the head jamb carefully insert the putty knife between the locking side stop

and jamb. Gently pry the stop away from the jamb and remove by twisting the stop toward

the exterior.

8. Observe how the locking hardware is located on the operating jamb and

exactly

which

primary and secondary cam receiving holes the tie bar is using.

NOTE: The tie bar

must

be inserted in the top hole of the primary cam and the center slot of

the secondary cam.

9. Remove the primary and secondary lock assemblies by removing #8 x 1

″

Phillips

panhead wood screws.

TOOLS NEEDED

INSTALLING NEW SEQUENTIAL LOCK ASSEMBLIES

NOTE: The redesigned keeper features a lengthened “throat”

that can easily be seen if an “old” and “new style” keeper are

set side by side.

NOTE: Units manufactured after December 12, 1994 feature an updated

sequential locking system and a date of manufacture stamp (located

under the hardware cover). If locking problems are experienced with a unit

manufactured after this date, contact your Marvin representative.

10. Install the new primary and secondary lock assemblies

using #8 x 1

″

Phillips panhead wood screws. Check

operation.

11.

Remove and install new keeper(s) on sash using

#8 x 1

″

Phillips flathead wood screws.

12.

Install the side stop by inserting the vinyl barb into

weatherstrip kerf. Roll side stop to the interior and seat

barb into jamb kerf.

NOTE: Do not force or hammer side stop into kerf as this may

damage side stop or jamb.

13. Insert head jamb and sill weatherstrip into kerf, followed

by side jamb weatherstrip.

14. Install head jamb stop and hardware cover into kerf.

15. Reinstall folding handle and cover.

16. Check operation by closing and locking window. Unit

should lock easily. If locking problems persist, contact

your Marvin representative.

WARNING: Practice safety! Wear safety glasses

or goggles and appropriate hearing protection.

SWINGING WINDOWS HARDWARE--CASEMASTER

SEQUENTIAL LOCK REPLACEMENT