Summary of Contents for BALTIMORE MONACO NAPLES

Page 34: ...DRAWING 1 PILOT ASSEMBLIES ALSO MONACO ACC ALSO MONACO ECS 33 ...

Page 35: ...DRAWING 2 PLACEMENT OF EMBERS 34 ...

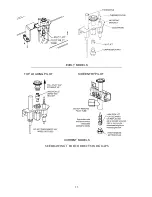

Page 36: ...DRAWING 4 GAS VALVES SEE 3 1 6 FOR NAPLES SEVILLE VALVE 35 ...

Page 38: ...DRAWING 7 LOG POSITIONING BALTIMORE MONACO NAPLES SEVILLE 37 ...

Page 39: ...DRAWING 8 REAR VIEW STANDARD MODELS 38 ...

Page 40: ...DRAWING 9 REAR VIEW ACC MODELS 39 ...

Page 41: ...DRAWING 10 REAR VIEW RMT MODELS 40 ...