Operator's

Safety

and

Service

Manual

RAMMERS

L12219 / 06.01

MBW Inc 2001

Printed in U.S.A.

MBW INC.

250 HARTFORD ROAD

P.O. BOX 440

SLINGER, WI 53086-0440

PHONE: (262) 644-5234

FAX (262) 644-5169

MBW CORPORATE INTERNET ADDRESS

E-MAIL: mbw@mbw.com

WEB SITE: www.mbw.com

IN ENGLAND:

MBW (UK) LIMITED

Bradley Fold Trading Estate Unit 6

Radcliffe Moor Road

Bolton BL2 6RT

Phone: 01204 387784

FAX: 01204 387797

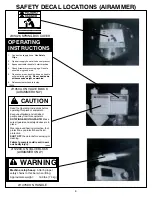

It is the OWNER'S RESPONSIBILITY to communicate information on the

SAFE USE and OPERATION of this machine to the operators!

Summary of Contents for R270R

Page 29: ...27 FIGURE 7 270 450 451 GEARBOX ...

Page 31: ...29 FIGURE 8 374 376 GEARBOX ...

Page 33: ...31 FIGURE 9 270 450 451 LOWER SYSTEM ...

Page 35: ...33 FIGURE 10 374 376 LOWER SYSTEM ...

Page 37: ...35 FIGURE 11 270 450 451 HANDLE ...

Page 39: ...37 FIGURE 12 STANDARD HANDLE OIL INJECTED ONLY ...

Page 41: ...39 FIGURE 13 374 376 HANDLE ...

Page 43: ...41 FIGURE 14 LO PROFILE HANDLE 1 3 6 10 11 13 11 9 ...

Page 45: ...43 FIGURE 15 LO PROFILE HANDLE OIL INJECTED ONLY ...

Page 49: ...47 FIGURE 17 ROBIN ENGINE ...

Page 51: ...49 FIGURE 18 ROBIN OIL INJECTED ENGINE ...

Page 53: ...51 FIGURE 19 LO PROFILE ROBIN ENGINE ...

Page 55: ...53 FIGURE 20 AIRAMMER MOTOR 2 6 5 4 3 1 9 8 7 TO VALVE BLOCK TO MOTOR INLET ...