ASG-32 Glider

Assembly Instructions

Important notification

1.The model is supplied with UFO and 502 glue. UFO is for bonding foam parts, and 502 for

bonding wood, carbon fiber and metal parts. 502 glue will cause serious corrosion to foam parts.

2.Please wait for the glue to dry and solidify in each installation step before the next ins tallation.

3.Please avoid using flame to heat the heat shrinkable tube on the model. Electric iron shall be

used for heating.

4.Please use razor blade to remove the parts from the plate. Do not tear the parts by force.

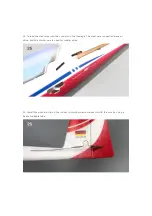

1. Fuselage internals