TECHNICAL & SERVICE MANUAL

Air-Conditioners For Building Application

<Indoor unit>

2004

Models

Ceiling Concealed

Series PEFY

PEFY-P40VMH-E,PEFY-P50VMH-E

PEFY-P63VMH-E,PEFY-P71VMH-E

PEFY-P80VMH-E,PEFY-P100VMH-E

PEFY-P125VMH-E,PEFY-P140VMH-E

PEFY-P200VMH-E,PEFY-P250VMH-E

INDOOR UNIT

CONTENTS

SAFETY PRECAUTIONS ·························

1

1. FEATURES ···········································

3

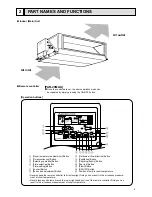

2. PART NAMES AND FUNCTIONS ········4

3. SPECIFICATION···································

6

4. OUTLINES AND DIMENSIONS············9

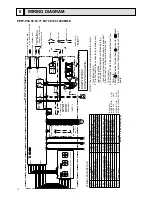

5. WIRING DIAGRAM ·····························

11

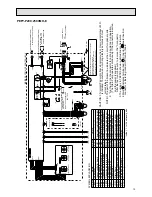

6. REFRIGERANT SYSTEM DIAGRAM 13

····

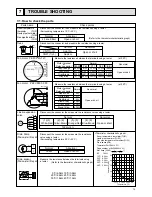

7. TROUBLE SHOOTING·······················

14

8. DISASSEMBLY PROCEDURE···········17

For use with the R410A & R407C & R22