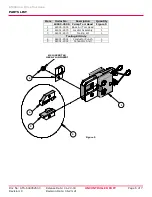

AT2080 Air Crimp Tool Head

Doc No: ATS-640052500

Release Date: 01-20-03

UNCONTROLLED COPY

Page 1 of 7

Revision: C

Revision Date: 06-23-21

Application Tooling Specification

FEATURES

Quick-change tool head for the 19279-0001 (AT-200)

Tooling kit is interchangeable with other kits in the 64001 and 64003 Series

A precision user-friendly terminal locator wire stop holds terminals in the proper crimping position

Pneumatic powered crimp tools help reduce fatigue and discomfort from repetitive manual crimping

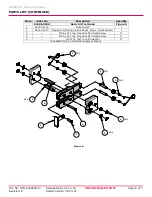

SCOPE

Products: Nylon closed-end connectors 8 AWG. This tool head is intended for use in the 19279-0001

(AT-200), either handheld or with optional bench adapter 19078-0307 (ATBA) and foot switch.

Wire Size: 8 AWG, 8.50mm²

Terminal Order No. Terminal Engineering No. (Ref.)

Wire Strip Length

Wire Combinations

mm

In.

19160-0024

NC-8

Varies

Varies

See Chart 1

19160-0144

NC-8

Varies

Varies

See Chart 1

Testing: Mechanical

The tensile test, or pull test, is a means of evaluating the mechanical properties of the crimped

connections. The following charts show the UL specifications for various wire sizes. The tensile

strength is shown in pounds and indicates the minimum acceptable force to break or separate the

terminal from the conductor.

Wire Size (AWG)

*UL486 C

8

45

*UL486 C: Closed-end connectors and wire nuts

Order Number

64005-2500

Engineering No.

AT 2080