MPD-152

Motor Protection Device

Over/Under Current

Over/Under Frequency

Over/Under Voltage

Single Phase Prevention

Short Circuit

Unbalance

Phase Loss

Lock Rotor Point

Phase Sequence

User Selectable Trip Time

Auto/Manual Reset Function

True RMS Measurement

INPUT :

Voltage AC

Direct Voltage AC

30 to 300V(L - N)

50 to 520V(L - L)

Burden

Voltage AC

Current AC

Burden

Primary CT Ratio

Secondary Current AC

Overload

Frequency

Up to 6A continuous

45.0 to 65.0 Hz

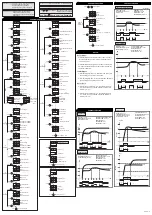

DIMENSION :

Size (mm)

NETWORK SELECTION :

3 Phase - 4 Wire,

TRIP SETTING :

Under Current

0.00 to CTR

0.00 to CTR

Over Current

FEATURES

Protection Available

Under Voltage

50 to 520V For 3Ø - 3W

30 to 300V For 3Ø - 4W

Over Voltage

50 to 550V For 3Ø - 3W

30 to 330V For 3Ø - 4W

Over / Under Frequency

45.0 to 65.0 Hz

Lock Rotor Point

0.5 to 9.0 Scale

Short Circut

1 - 9 Scale

Unbalance

5 - 60%

TIME PARAMETER :

Power On Delay

0 to 99 Sec

Initial Time Delay

0 to 99 Sec

Trip Delay Time

0 to 999 Sec

(Voltage, Current, Frequency,

SSP, Unbalance)

Scrolling Time

1 to 99 Sec

Reset Time

0 to 99 Sec

OUTPUT SPECIFICATION :

Relay

1 Nos

Relay Type

Supply Voltage

100 to 270V AC, 50Hz

Power Consuption

3VA @ 230 AC MAX

Rating

10Amp, 250V AC

AUXILIARY SUPPLY :

KEY OPERATION

To View Individual Parameters Value

OR

Operator Mode

To Reset The Relay Contact manually after

Tripping

Parameter Setting Mode

TECNICAL SPECIFICATION

3 Phase - 3 Wire,

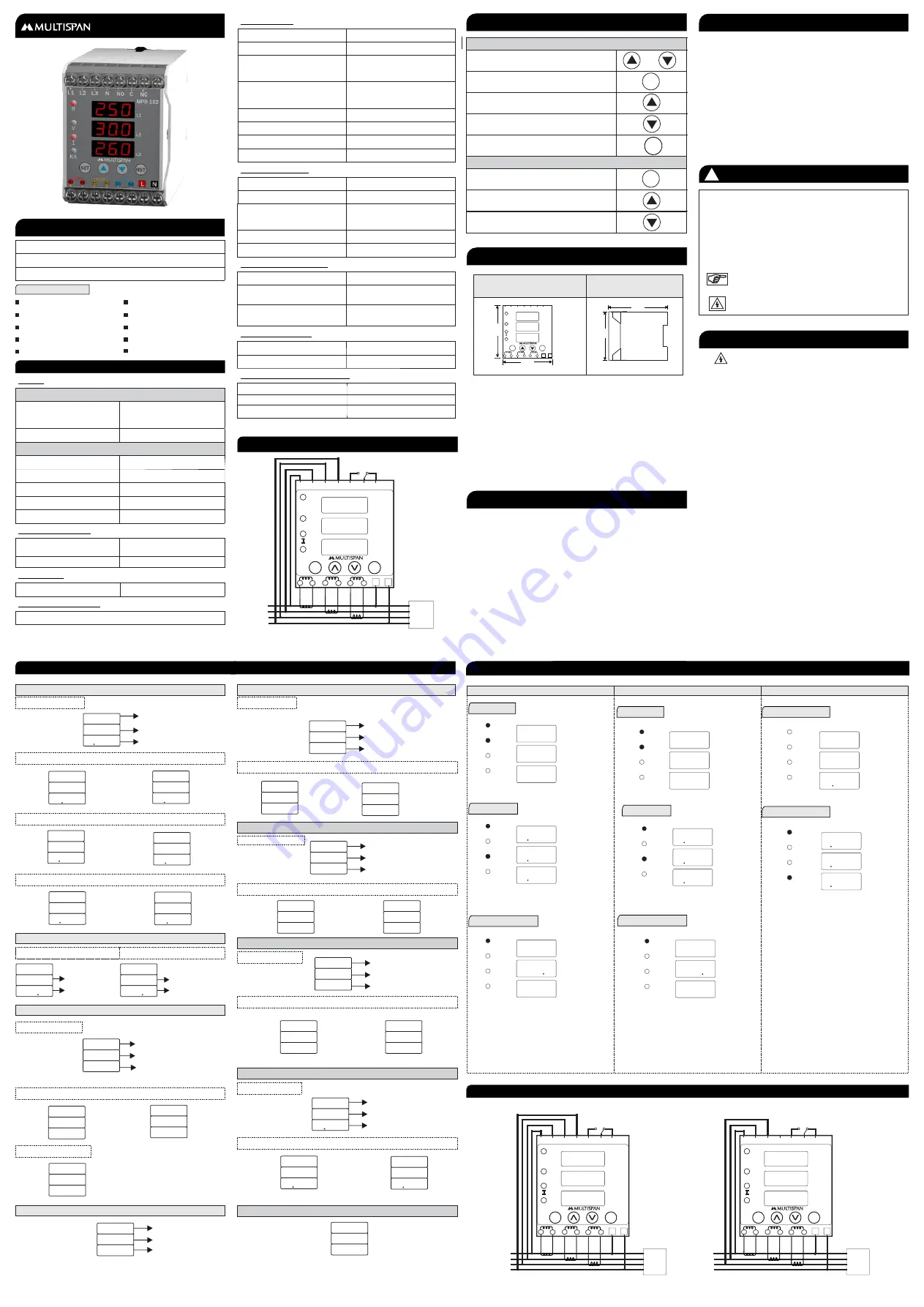

TERMINAL CONNECTION

MAINTENANCE

MECHANICAL INSTALLATION

Under Current fault Message

1) Unc in R Phase

2) Unc in Y Phase

3) Unc in B Phase

4) Unc in RY Phase

5) Unc in YB Phase

6) Unc in RB Phase

7) Unc in RYB Phase

Under Current

R phase Current Value

U N C

R

2 8 7

Fault in R phase

U N C

Y

2 7 2

U N C

B

2 6 3

U N C

R Y

2 7 0

U N C

Y B

2 6 0

U N C

R B

2 5 5

U N C

R Y B

2 5 5

Over Frequency Fault Message

Over frequency

Frequency Value

O V F

5 2 6

Unbalance Fault Message

1) Unb in R Phase

2) Unb in Y Phase

3) Unb in B Phase

4) Unb in RYB Phase

Unbalance

Unbalance Percentage

Between R & B Phase

U N B

R B

5 5

Fault Between R & B Phase

U N B

R y

5 9

U N B

Y B

5 7

U N B

R Y B

5 5

Phase Loss Message

1) R Phase loss

2) Y Phase loss

3) B Phase loss

Phase

Loss

P H A

R

L O S

P H A

Y

L O S

P H A

B

L O S

Phase Sequence Message

Phase

Fault

P H A

S E Q

F L T

Sequence

< 0.2VA

5 to 6000 Amp selectable

ENVIRONMENTAL CONDITION :

Working Temperature

Storage Temperature

Relative Humidity

0 to 55°C

0 to 55°C

95 % RH Non-Condensing

FAULT MESSAGE

To Enter In Parameter Setting Mode

To View The Voltage Page While Display

Indicate fault

To View The Current Page While Display

Indicate fault

Edited Parameter Value to be Set, And Move

to the Next Step

To Increment Parameter Value

To Decrement Parameter Value

1)

V

LN

Page

< 0.2VA

WIRING CONNECTION

1) 3 Phase - 4 Wire

2) 3 Phase - 3 Wire

Page - 1

3)

Frequency

Page

R

0.5 to 5 Amp

3

ø

- 4W NETWORK CONNECTION

1)

V

LL

Page

2) Amp Page

1) Fault Massage

2) KA Page

L1

L2

L3

V

R

I

KA

2 4 0

2 4 0

2 4 0

f R Q

5 0 0

H Z

4 2 0

4 2 0

4 2 0

r

U N C

2 8 7

1 2 0

1 2 0

1 2 0

Under Frequency Fault Message

Under frequency

Frequency Value

U N F

5 2 6

Single Phase Prevention Fault

S P P

R

1 0 0

R Phase Fault

Single Phase Prevention

R - Phase Voltage Value

2) SPP in Y Phase

S P P

Y

1 0 5

3) SPP in B Phase

S P P

B

1 1 0

R

L O S

S P P

Y

L O S

S P P

B

L O S

S P P

Lock Rotor Point

L R P

R

5 0 0

R Phase Fault

Lock Rotor Point

Phase Currunt Value

L R P

Y

5 0 0

L R P

B

5 0 0

Frequency Fault Message

SPP Fault Due to Phase Loss

Single Phase Prevention

R Phase

Loss

1) SPP in R Phase

1) SPP in R Phase

2) SPP in Y Phase

3) SPP in B Phase

1) LRP in R Phase

2) LRP in Y Phase

3) LRP in B Phase

3

ø

- 3 W NETWORK CONNECTION

3

ø

- 3W / 3 - 4W NETWORK CONNECTION

Neutral Loss

1 C/O (NO-C-NC)

DISPLAY PAGES

SET

S1

S2

S1

S2

S1

S2

L1

L2

MPD 152

L3

L1

L2

R

V

KA

L3

N

NO

C

NC

RST

L

N

DISPLAY AND KEYS :

Display

3 Digit, 3 Line 7 Seg 0.28”,

RED LED

Keys

SET, INC, DEC, RST

L1

L2

L3

V

R

I

KA

2)

Amp

Page

5 0 0

5 0 0

5 0 0

L1

L2

L3

V

R

I

KA

L1

L2

L3

V

R

I

KA

L1

L2

L3

V

R

I

KA

5 0 0

5 0 0

5 0 0

f R Q

5 0 0

H Z

L1

L2

L3

V

R

I

KA

L1

L2

L3

V

R

I

KA

L1

L2

L3

V

R

I

KA

SET

RST

S1

S2

S1

S2

S1

S2

L

N

L1

L2

MPD 152

L3

L1

L2

V

KA

L3

N

NO C

NC

L1

L2

L3

N

TO

LOAD

R

SET

RST

S1

S2

S1

S2

S1

S2

L

N

L1

L2

MPD 152

L3

L1

L2

V

KA

L3

N

NO C

NC

L1

L2

L3

N

TO

LOAD

R

SET

RST

S1

S2

S1

S2

S1

S2

L

N

L1

L2

MPD 152

L3

L1

L2

V

KA

L3

N

NO C

NC

L1

L2

L3

N

TO

LOAD

R

Front View (mm)

Side View(mm)

1) To install the instrument on a DIN rail, raise the clamp at the

back of the instrument and place it on the rail. Now release

the clamp, so the instrument fits on the DIN rail.

2) Ensure proper fitting of the instrument by pulling it outwards.

3) To remove the instrument raise the clamp to release it from

the DIN rail.

4) The equipment in its installed state must not come in close

proximity to any heating source, caustic vapors, oil steam, or

other unwanted process byproducts.

5) Do not connect anything to unused terminals.

Read complete instructions prior to installation

and operation of the unit.

WARNING :

Risk of electric shock.

SAFETY PRECAUTION

!

All safety related codifications, symbols and instructions

that appear in this operating manual or on the equipment

must be strictly followed to ensure the safety of the operating

personnel as well as the instrument.

If all the equipment is not handled in a manner specified

by the manufacturer, it might impair the protection provided

by the equipment.

WARNING GUIDELINES

WARNING : Risk of electric shock.

1) To prevent the risk of electric shock, power supply to the

equipment must be kept OFF while doing the wiring

arrangement. Do not touch the terminals while power is

being supplied.

2) To reduce electro magnetic interference, use wire with

adequate rating and twists of the same of equal size shall

be made with shortest connection.

3. Cable used for connection to power source, must have a

cross section of 1mm or greater. These wires should have

insulations capacity made of at least 1.5kV.

4) A better anti-noise effect can be expected by using

standard power supply cable for the instrument.

1) Do not allow pieces of metal, wire clippings, or fine

metallic fillings from installation to enter the product or

else it may lead to a safety hazard that may in turn

endanger life or cause electrical shock to the operator.

2) Circuit breaker or mains switch must be installed

between power source and supply terminal to facilitate

power ‘ON’ or ‘OFF’ function. However this mains switch

or circuit breaker must be installed at convenient place

normally accessible to the operator.

INSTALLATION GUIDELINES

3) Use and store the instrument within the specified ambient

temperature and humidity ranges as mentioned in this

manual.

1) The equipment should be cleaned regularly to avoid blockage

of ventilating parts.

2) Clean the equipment with a clean soft cloth. Do not use

isopropyl alcohol or any other cleaning agent.

MAINTENANCE

3) Fusible resistor must not be replaced by operator.

SET

SET

RST

240

240

240

75(H)X 55(W)X110(D)

75

55

110

Neutral Loss Message

R

1 5 8

S P P

NOTE : Neutral loss Protection available Only,

In Case Of SPP Enable

75

MAINTENANCE

MAINTENANCE

3)

Frequency

Page