S82 W18717 Gemini Drive

Muskego, Wisconsin 53150

Phone: (877) 622-2694

Fax: (888) 679-3319

www.nabcoentrances.com

Technical Support: (866) 622-8325

WARNING

• Turn OFF all power to the Automatic Door if a Safety System is not working.

• Instruct the Owner to keep all power turned OFF until corrective action can be achieved by a NABCO

trained technician. Failure to follow these practices may result in serious consequences.

• NEVER leave a Door operating without all Safety detection systems operational.

Part #C-00140

Rev. 10/7/16

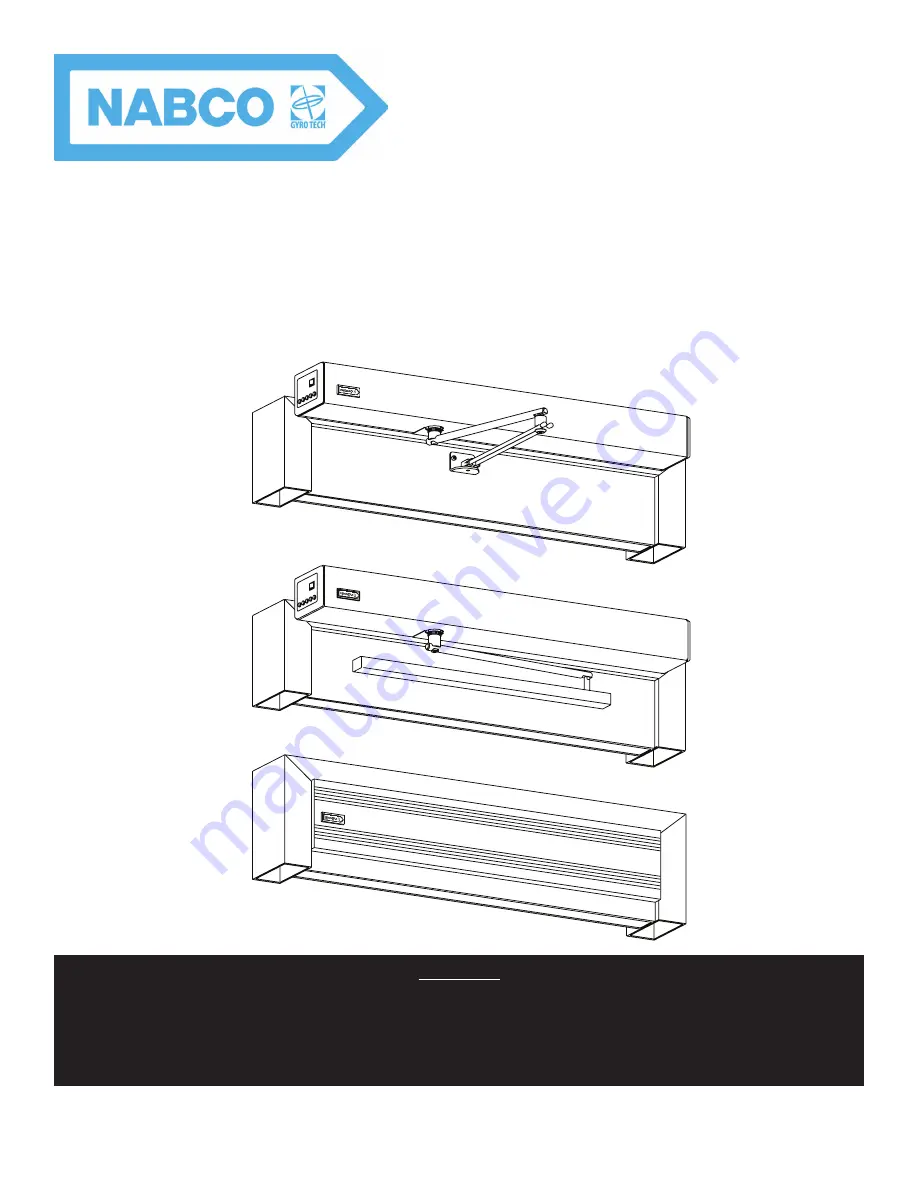

GT20 Swing Door Operator

Wiring and Programming Manual

**With GT20 Control**

DN 1145