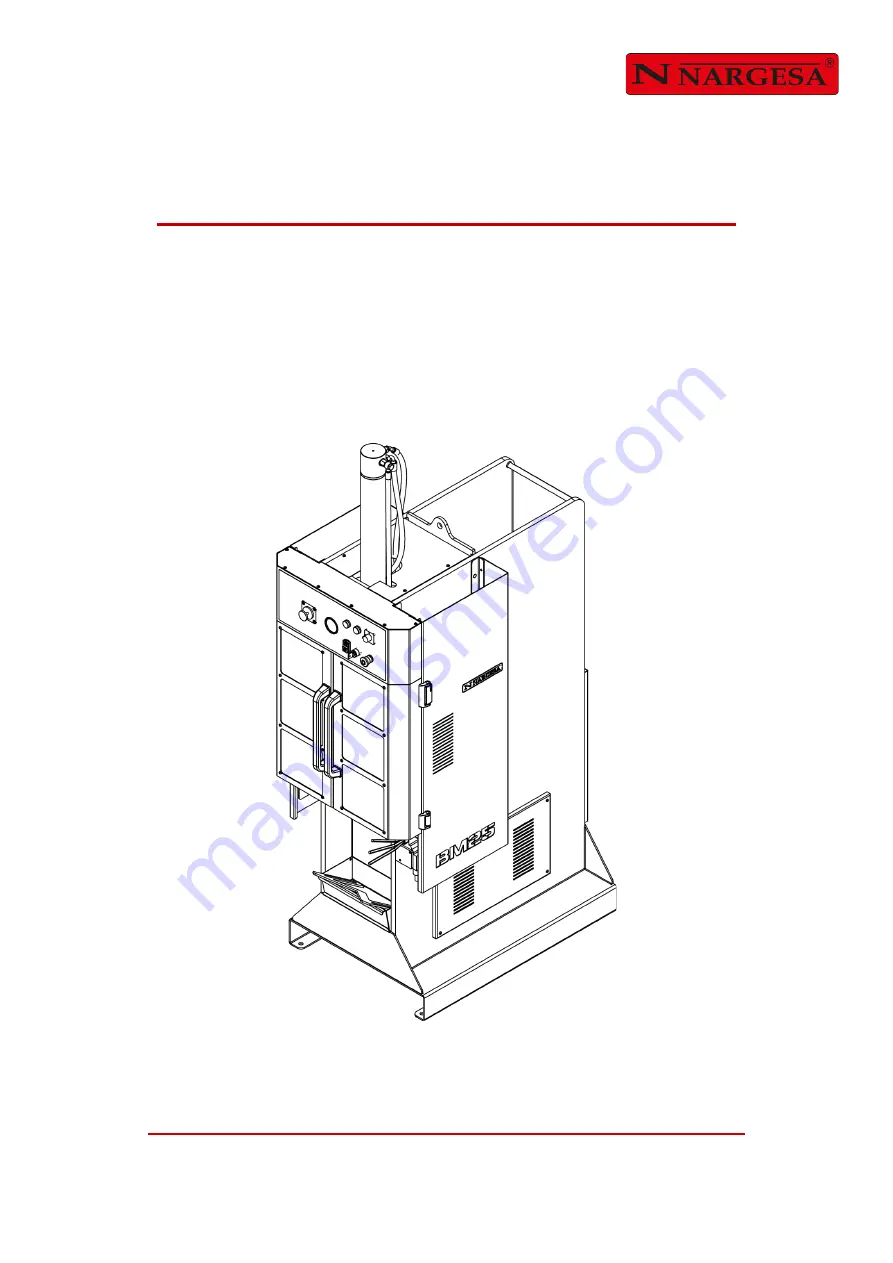

Summary of Contents for BM25

Page 2: ...Thank you for choosing our machines www nargesa com...

Page 18: ...18 VERTICAL BROACHER BM25 6 TABLE OF CHARACTERISTICS OF BRUSHES 6 1 Millimeter keyway broaches...

Page 19: ...19 6 2 Inches keyway broaches...

Page 20: ...20 VERTICAL BROACHER BM25...

Page 35: ...A3 VERTICAL BROACHER BM25 A1 List of parts...

Page 36: ...A4...

Page 37: ...A5 VERTICAL BROACHER BM25...

Page 38: ...A6...

Page 39: ...A7 VERTICAL BROACHER BM25...

Page 40: ...A8 A2 Piston assembly...

Page 41: ...A9 VERTICAL BROACHER BM25...

Page 42: ...A10 A3 Hydraulic group...

Page 43: ...A11 VERTICAL BROACHER BM25...

Page 44: ...A12...

Page 45: ...A14 A4 Electric box...

Page 46: ...A15 VERTICAL BROACHER BM25...

Page 47: ...A16...