NEMIC-LAMBDA

SWS

50

⋅

75

⋅

100

⋅

150

Series

INSTRUCTION MANUAL

SWS50

⋅

75

⋅

100

⋅

150 Series

Instruction Manual

BEFORE USING THE POWER SUPPLY UNIT

Pay attention to all warnings and cautions before using the unit. Incorrect usage could lead to an electrical

shock, damage to the unit or a fire hazard.

WARNING and CAUTION

Do not modify.

Do not touch the internal components, they may have high voltage or high temperature. You may get electri-

cal shock or burned.

When the unit is operating, keep your hands and face away from it, you may get injured by an accident.

This power supply is primarily designed and manufactured to be used and enclosed in other equipment. Stick

the WARNING label for users on the system equipment and describe the notice in the instruction manual.

Never operate the unit under over current or shorted conditions for 30 seconds or more and out of Input volt-

age range in specification, which could result in damage or insulation failure. There is no possibility for fire

or burning.

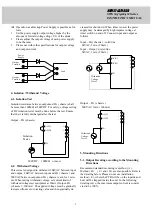

Confirm connections to input/output terminals are correct as indicated in the instruction manual.

Do not drop or apply shock to power supply unit.

Note: CE MARKING

CE Marking, when applied to a product covered by this handbook indicates compliance with the low voltage

directive (73/23/EEC) as modified by the CE Marking Directive (93/68/EEC) in that it is complies with

EN60950

NEMIC-LAMBDA

SWS

50

⋅

75

⋅

100

⋅

150

Series

INSTRUCTION MANUAL

DWG NO. : CA732-04-01

APPD CHK DWG