NEWTON TITAN NP400 – INSTALLATION INSTRUCTIONS

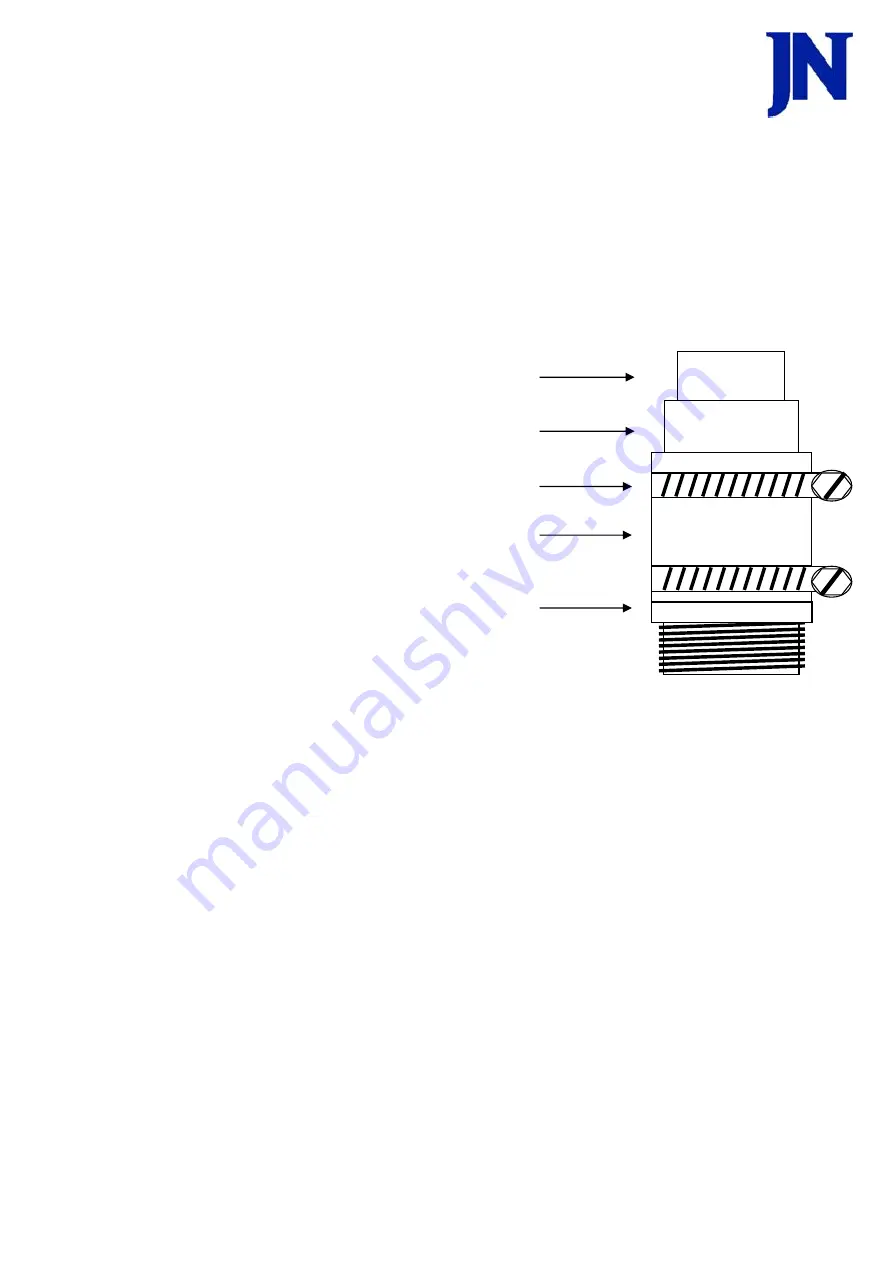

The pump is supplied with a one-way valve (check valve). This prevents water within the discharge

pipe falling back into the chamber. The check valve is the interface for connecting the waste pipe.

The check valves supplied are designed to be used with 40mm PVC solvent weld waste pipe. This

is the standard pipe found in all plumbing supplies and DIY stores. The check valves have a rubber

coupling above the one-way valve. Check the direction of flow to ensure the valve is facing the

correct way. This rubber coupling has an internal diameter of 48mm and has a jubilee clip for

tightening to the waste pipe.

You need a 40mm waste pipe straight connector to fit into the rubber coupling. These have an

external diameter of 48mm and fit into the rubber coupling. 40mm waste pipe then fits into the

straight connector.

Use of two NP400’s in a two-pump installation

In a two-pump installation, it is beneficial to have one pump set to start before the other so that the

alarm has space to operate in the event of failure of pump one. It is very simple to set one switch

above the other so that one NP400 pump to comes on before the other.

ELECTRICAL CONNECTION

The unit should be wired to either a socket via a plug, or hard wired. In both instances, a 5 amp fuse

should be used. It is advised that an independent feed be used from the consumer box so that the

unit is not affected by the tripping out of other electrical devices.

WARRANTY

The pump has a 1-year warranty from the date of proven first installation or the date of sale if this

cannot be proven. If the pump fails within this period we will replace the pump and investigate the

failure. If the failure is due to negligence or miss-use, all warranties are voided. If the pump is found

to be in full working order, it will be returned, and any replacement pump sent to you will be billed

for.

Bottom of check valve

Rubber coupling

Jubilee clip

40mm straight PVC coupling

40mm PVC waste pipe

It is advisable to put some

form of demountable

connection to the horizontal

pipe within the chamber to

allow easy removal of the

pump system for maintenance.

Rubber couplings or rubber in-

line check valves can be used

for this.