Summary of Contents for Super Coolscan 9000 ED

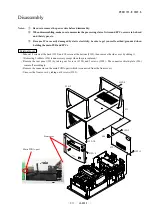

Page 25: ...VRA51701 R 3607 A A12 LS 9000 Stage carriage unit Place wires in position ...

Page 64: ...VRA51701 R 3607 A E1 LS 9000 ブロック図 BLOCK DIAGRAM ...

Page 74: ... ...

Page 75: ...A ...

Page 76: ... ...

Page 77: ... ...

Page 78: ... ...

Page 79: ...G F 2 0 ...

Page 80: ... ...

Page 81: ... ...

Page 82: ... ...