Reviews:

No comments

Related manuals for CP65

GCD4

Brand: BLUEROCK Pages: 16

BH-G 726

Brand: EINHELL Pages: 58

2615-20

Brand: Milwaukee Pages: 9

PCC620

Brand: Porter-Cable Pages: 40

TH-5S

Brand: Toku Pages: 7

3241GRILL20SEB03

Brand: Kamado Pages: 8

GC252D50

Brand: T-Fal Pages: 35

BBA92

Brand: BORETTI Pages: 111

720-0888B

Brand: Nexgrill Pages: 20

463371116

Brand: Char-Broil Pages: 56

KMCTC-24

Brand: Kitchen Monkey Pages: 14

ARENA MIDNIGHT

Brand: Barbecook Pages: 112

146471.01

Brand: ENKHO Pages: 44

STDH7213C

Brand: Stanley Pages: 22

SAF 001G

Brand: Safire Pages: 60

MD120/4

Brand: AGP Pages: 44

SCB25

Brand: Vulcan-Hart Pages: 32

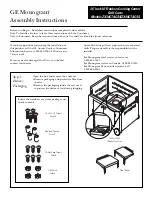

ZX48CTACSS

Brand: GE Pages: 4