Summary of Contents for PACEMARK 4410

Page 2: ...1 PACEMARK 4410 PRINTER Service Manual...

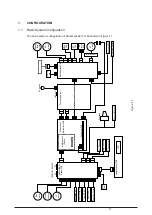

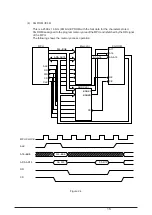

Page 53: ...52 Figure 3 1 3 2 Parts Layout...

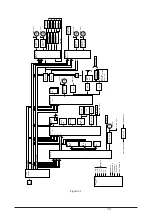

Page 96: ...95...

Page 152: ...151 No Yes End Replace PHA Board Recovered No Yes End Replace PMA Board...

Page 180: ...120 Knob Assy 40782001 8 4 6 3 5 10 7 1 2 9...

Page 182: ...122 Ribbon Assy Feed 40506101 1 15 8 7 8 14 6 5 10 13 3 4 13 2 6 7 14 9 11 11 1...

Page 184: ...124 Sprocket Assy L 40507601 3 2 5 6 1 19 19 7 4 21 10 8 9 20 18...

Page 186: ...126 Sprocket Assy R 40508101 3 7 11 11 1 6 5 2 13 4...

Page 190: ...130 Sheet Feeder Assy R Rear 40509101 8 11 1 9 4 13 13 10 6 5 2 9 12 7 3 Pin Protrusion...

Page 196: ...136 Front Cover Assy 40677201 ODA 40677202 OEL 10 6 9 9 9 2 4 4 1 3 7 7 5 9 10 10 6 6...

Page 198: ...138 Rear Cover Assy 40678301 11 6 5 9 10 10 8 10 10 10 9 4 1 10 3 2 7 13...

Page 202: ...142 Frame Assy OpePane 40755801 3 2 4 6 8 9 9 1 5...

Page 204: ...144 PMA PDA PCB Assy 40752201 4075202 4 or 6 5 or 7 1 or 2 3 8 9 11...