Installation, Operation &

Service Manual

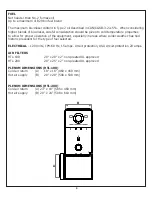

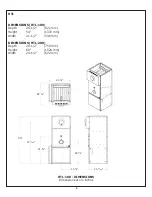

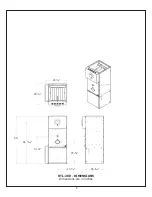

OIL FIRED LOBOY FURNACE - 83% + EFFICIENCY

2023-08-01

5IM-OE-HTL0-00

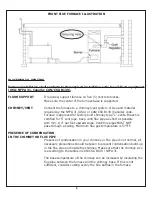

INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL CODES THAT MAY

DIFFER FROM THIS MANUAL

Please read the manual in its entirety before beginning installation. This

manual must be kept with the boiler for future reference. For maintenance

or question, please refer to your installer – contractor directly.

HTL-100

HTL-200