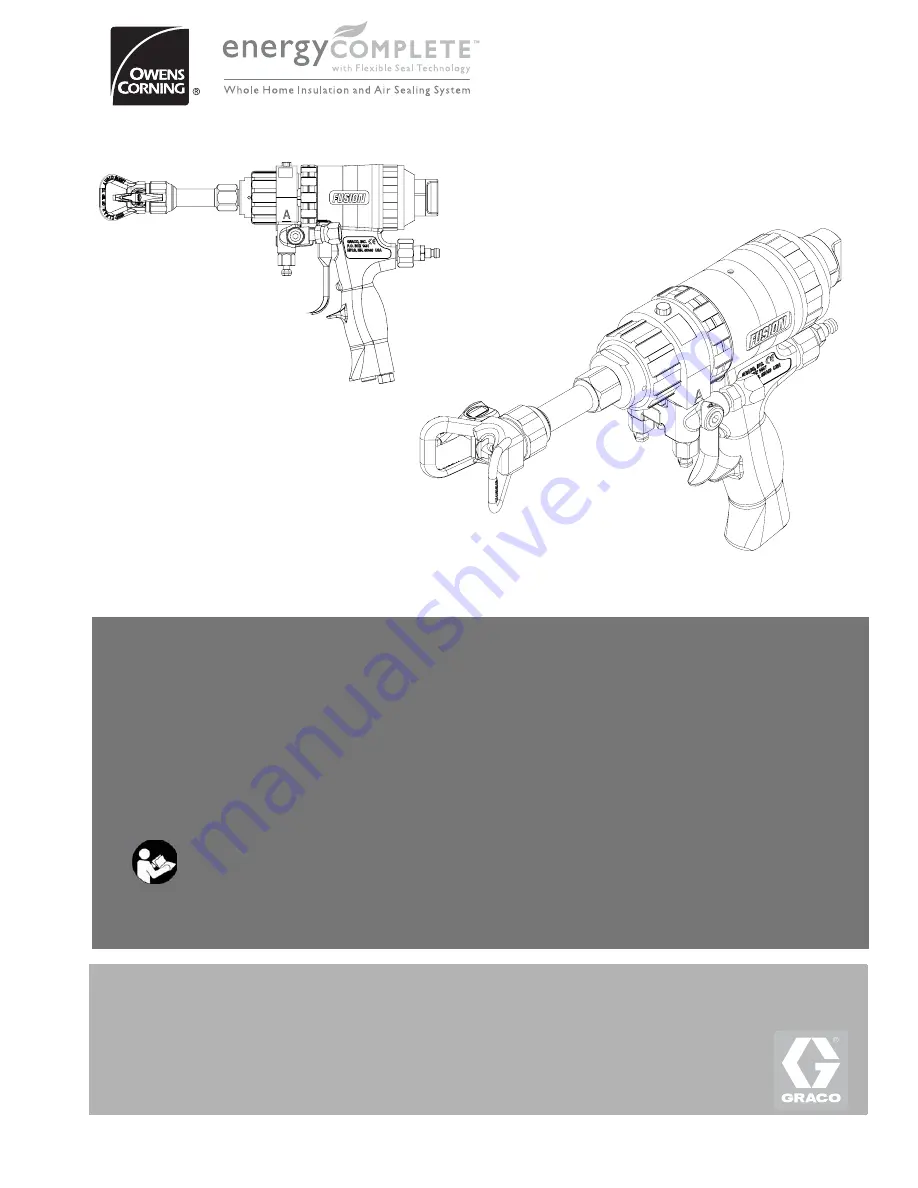

Instructions & Parts

r_256998_313294_1b

US Patent Number 7,036,171

Korean Patent 338185

Australian Patent Number 152610

2004230905

EP 1610904

r_256998_313294_10b

EnergyComplete

™

Spray Gun

Manual No:

For use with EnergyComplete Spray Foam with Flexible Seal Technology.

Not for use in explosive atmospheres or with flammable materials.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

256998 EnergyComplete Spray Gun with Static Mixer Assembly

3500 psi (24.2 MPa, 242 bar) Maximum Fluid Working Pressure

80-130 psi (0.55-0.9 MPa, 5.5-9.1 bar) Air Inlet Pressure Range

200°F (94°C) Maximum Fluid Temperature

313294D