CS/CU-YW9DKE

CS/CU-YW12DKE

Air Conditioner

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-techical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

1 Features

2

2 Functions

3

3 Product Specifications

6

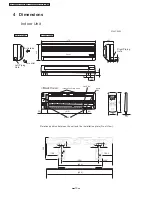

4 Dimensions

11

5 Refrigeration Cycle Diagram

12

6 Block Diagram

13

7 Wiring Diagram

14

8 Operation Details

15

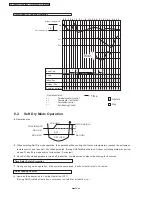

9 Installation instructions

29

10 Installation and Serving Air Conditioner Using R410A - - - - -

11

Disassembly of The Parts

12 Troubleshooting Guide

13 Technical Data

14 Exploded View

15 Replacement Parts List

16 Exploded View

17 Replacement Parts List

18 Electronic Circuit Diagram

CONTENTS

Page

Page

Order No.

Guangzhou Matsushita Air Conditioner Co., Ltd.

(GMAC) All rights reserved. Unauthorized copying

and distribution is violation of law.

C

R

49

50

53

55

58

59

60

61

62

------------------------------------------------------

--------------------------------------------------------

------------------------------------------

-----------------------------------------------------

-----------------------------------

--------------------------------------------------

-------------------------------------------------

-----------------------------------------------

---------------------------------------------------

--------------------------------------

----------------------------------------

--------------------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------

R

OFF

MODE

TEMP

OFF/ON

ON

CANCEL

SET

STD

TIMER

FAN

SPEED

AIR

SWING

GMAC0504037C3