Service Manual

ORDER NO.HPD0011C18C1

MASSAGE LOUNGER

●

EP790-C1

SPECIFICATIONS

Power source

: 120V AC, 60Hz

Power consumption

: 230W

Kneading speed

: Approx. 28 times/min.

Tapping speed

: Approx. 500 times/min.(per side)

Rolling massage speed

: Approx. 1 cycle every 33 sec.

Massaging width

: Shoulder/lower back section : Approx. 75mm

Back rolling width/tapping width : Narrow : Approx. 85 mm/: Wide : Approx. 110 mm

Massage heads up/down travel

: Approx. 600 mm

Regional back rolling

: Automatic repetition within approx. 120mm range

Intensity adjustment

: Adjusts massage head protrusion steplessly within approx. 45 mm range

Shoulder position adjustment

: 7 steps

Automatic shut-off

: Approx. 15 min.

Leg massager - vibration

: Approx. 3200 cycles/min./ Shut-off timer : Approx. 30 min.

Dimensions (H x W x D)

:•Not reclined and leg rest retracted : 1,050 x 755 x 1,050 mm/ •Reclined and leg rest extended : 620 x 755 x 1,750 mm

Reclining angle

: Approx. 127° to 170°

Weight

: 56 kg

Accessories

: Back cushion, headrest

© 2000 Matsushita Electric Works, Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

Summary of Contents for EP790-C1

Page 2: ... TOP NEXT ...

Page 4: ... TOP PREVIOUS NEXT ...

Page 8: ... TOP PREVIOUS NEXT ...

Page 10: ... TOP PREVIOUS NEXT ...

Page 15: ...4 1 PARTS IDENTIFICATION TOP PREVIOUS NEXT TOP PREVIOUS NEXT ...

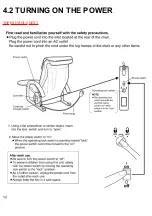

Page 16: ...4 2 TURNING ON THE POWER TOP PREVIOUS NEXT ...

Page 17: ...TOP PREVIOUS NEXT ...

Page 18: ...5 Required tools TOP PREVIOUS NEXT ...

Page 19: ...TOP PREVIOUS NEXT ...

Page 20: ...6 Simplified wiring diagram TOP PREVIOUS NEXT ...

Page 21: ... TOP PREVIOUS NEXT ...

Page 26: ......

Page 32: ... TOP PREVIOUS NEXT ...

Page 35: ... TOP PREVIOUS NEXT ...

Page 39: ... ...

Page 40: ...TOP PREVIOUS NEXT ...

Page 43: ... TOP PREVIOUS NEXT ...

Page 54: ...TOP PREVIOUS NEXT ...

Page 56: ......

Page 57: ... TOP PREVIOUS NEXT ...

Page 61: ...15 7 Assembling TOP PREVIOUS NEXT 15 7 1 Assembling the oval gear TOP PREVIOUS NEXT ...

Page 63: ... TOP PREVIOUS NEXT ...

Page 65: ... TOP PREVIOUS NEXT ...

Page 67: ... TOP PREVIOUS NEXT ...

Page 71: ...TOP PREVIOUS NEXT ...

Page 73: ... TOP PREVIOUS NEXT ...

Page 74: ...16 Arranging massage block lead wires TOP PREVIOUS NEXT ...

Page 75: ...TOP PREVIOUS NEXT ...

Page 76: ...17 Actual wiring diagram TOP PREVIOUS NEXT ...

Page 77: ... TOP PREVIOUS NEXT ...

Page 78: ...18 Trouble shooting TOP PREVIOUS NEXT ...

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ... TOP PREVIOUS NEXT ...

Page 86: ...19 3 Q A TOP PREVIOUS NEXT TOP PREVIOUS NEXT ...

Page 88: ...20 EXPLODED VIEW TOP PREVIOUS NEXT TOP PREVIOUS NEXT ...

Page 95: ......

Page 96: ......