©

2004 Matsushita Electric Industrial Co., Ltd. All

rights

reserved.

Unauthorized

copying

and

distribution is a violation of law.

TU-PT700U

GP7P Chassis

Digital Media Receiver

Specifications

Power Source

120 V AC, 60 Hz

Power Consumption

Maximum

45 W

Stand-by condition

22 W

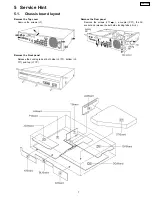

Dimensions (W × H × D)

16.9” (430 mm) × 3.4” (86 mm) × 14.8” (377 mm)

Mass (weight)

approx. 13.2 lbs

Channel Capability-ATSC / NTSC

VHF/ UHF : 2-69, CATV:1-135

FEATURES

Two screen display functions

LINEAR PIP

BBE VIVA 3D

V-Chip

CLOSED CAPTION

HDMI

3D Y/C FILTER

JPEG Viewer

CableCARD TM slot

Accessories Supplied

AC cord

Display-Receiver cable

Operating Condition

Temperature

32 °F - 104 °F (0 °C - 40 °C)

Humidity

20 % - 80 %

Connection Terminals

RGB INPUT

D-SUB 15pin

R,G,B / 0.7 Vp-p (75

W

)

HD VD / TTL Level (high impedance)

AV INPUT 1- 3

VIDEO (Phono Jack Type)

1.0 Vp-p (75

W

)

S-VIDEO (Mini DIN 4-pin)

Y : 1.0 Vp-p (75

W

) C : 0.286 Vp-p (75

W

)

AUDIO L-R (Phono Jack Type × 2)

0.5 Vrms

AV PROG. OUT

VIDEO (Phono Jack Type)

1.0 Vp-p (75

W

)

AUDIO L-R (Phono Jack Type × 2)

0.5 Vrms

AUDIO OUT

AUDIO L-R (Phono Jack Type × 2)

0.5 Vrms

COMPONENT VIDEO INPUT1-2

Y

1.0 Vp-p (including sync)

PB / PR

0.7 Vp-p

AUDIO L-R (Phono Jack Type × 2)

0.5 Vrms

HDMI/AUDIO INPUT

HDMI type A Connector

AUDIO L-R (Phono Jack Type × 2)

0.5 Vrms

DIGITAL AUDIO OUT

PCM / Dolby Digital, Fiber Optic

DISPLAY OUT

D-sub 26-pin, Digital RGB 24-pin

ORDER NO. ITD0411063C1

B19 Canada : B07