Magnum C3C Spreader Sprayer

Operator Manual

Refer to the cover page for restrictions regarding

reproduction or disclosure of this material.

Page 1

September/08

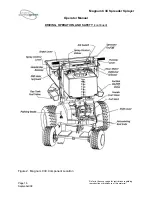

2009 MAGNUM SmartSteer

TM

C3C

Spreader Sprayer

Operator’s Manual

Model # MAGNUM SmartSteer

TM

C3C

Copyright © 2008, PermaGreen Supreme, Inc.

All rights reserved. No part of this book covered by the copyright hereon

may be reproduced or copied in any form or by any means, except as

permitted by the proprietary data statement for use with PermaGreen Supreme

equipment, without the written permission of PermaGreen Supreme, Inc.

For technical support

Contact your local dealer or PermaGreen Supreme,

Inc. at (800) 346-2001 or via e-mail at

tech@permagreen.com

PermaGreen Supreme, Inc.

September, 2008

Basic Issue