Reviews:

No comments

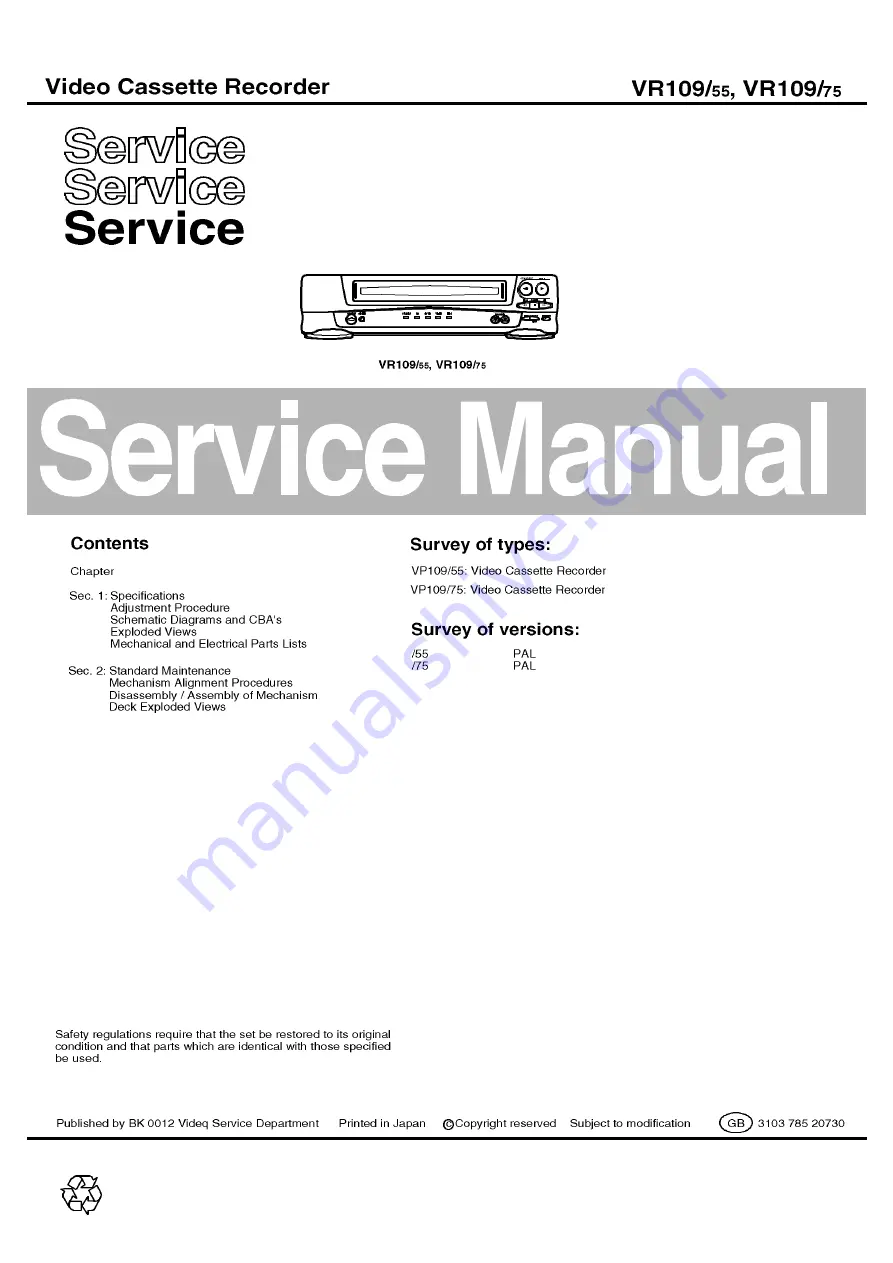

Related manuals for VR109/55

SLV-KF295TK

Brand: Sony Pages: 28

SLV-KF297MK2

Brand: Sony Pages: 32

SLV-KH7ME

Brand: Sony Pages: 48

SLV-KH7PL

Brand: Sony Pages: 52

SLV-L45AR

Brand: Sony Pages: 87

SLV-L56AR

Brand: Sony Pages: 134

VRC4101

Brand: Zenith Pages: 32

TT20A54X/XAX

Brand: Samsung Pages: 56

SRV196

Brand: Sylvania Pages: 48

DVCPRO50 AJ-D960EG

Brand: Panasonic Pages: 120

37TR126

Brand: Philips Pages: 28

21PV715

Brand: Philips Pages: 2

CCA191AT

Brand: Philips Pages: 60

32PW9576/12E

Brand: Philips Pages: 29

25PV815

Brand: Philips Pages: 2

CCA134AT

Brand: Philips Pages: 2

SLV-SE210B

Brand: Sony Pages: 52

VR602BMG

Brand: Magnavox Pages: 52