1

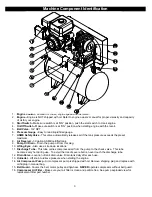

Gasoline Stationary Air Compressor

Installation, Operation and Maintenance Manual

To the Owner:

Thank you for purchasing a Powerhorse Air Compressor. Your machine is designed for long life,

dependability, and the top performance you demand! Please take time now to read through this manual so you

better understand the machine’s operation, maintenance and safety precautions. Everyone who operates this

machine must read and understand this manual. The time you take now will prolong your machine’s life and

prepare you for its safe operation. Enjoy the exceptional performance of your Powerhorse Air Compressor, the

industry leader!

The manufacturer reserves the right to make improvements in design and/or changes in specifications at any

time without incurring any obligation to install them on units previously sold.

Quick Facts

Engine Oil

Engine is shipped without oil. Fill before starting.

Use SAE 10W-30 motor oil.

Pump Oil

Check pump oil level before starting.

Use SAE 30W non-detergent pump oil (part # 4043).

Air Filter

Replacement air filter part number is #35409.

Maximum

Pressure

Item #46851 maximum pressure = 175 psi

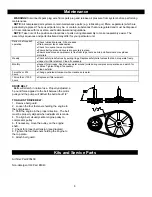

Maintenance

Schedule

Engine:

Oil: change after first 20 hours, then annually or every 100 hours.

Spark Plug: clean every 100 hrs., replace annually or every 300 hrs.

Air Filter: clean weekly, replace annually or every 1000 hrs.

Refer to your Powerhorse engine owner’s manual for further

instructions.

Tank:

Drain water daily.

Compressor

Pump:

Oil: change after first 50 hours, then every 3 months or 500 hours.

Read and understand all manuals before operating.

Any Questions, Comments, Problems or Parts Orders

Call Powerhorse Product Support 1-866-443-2576

46851; 414cc Powerhorse Engine,

30 Gal. Stationary

M46851C