Note:

Unless ordered seperatley the

cylinder is not included in this kit.

Note: If, when fitting the pull handle, the screws make direct contact with the lock-case, please use the shorter (5/8“) screws

included in the fixing pack.

Standard Primera Products are designed for internal applications only. For external applications products plated to “Service

Condition 5” should be used.

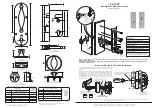

1-46-729C

Anti-Ligature Bedroom Lockset

PR6130RBD

Roller Bolt

Dead lock

70

PR⁴-⁵⁸E

Euro Profile

Escutcheon

70

PR7101-TPSP

Thumb Turn

Support Plate

PR4-728-TP

Anti-ligature

Turn/Pull

To adjust Roller Catch projection turn

screw

anti-clockwise to

increase or clockwise

to withdraw

(Max adjustment

6.5mm – 13mm)

Description

Roller Bolt Deadlock 103x235

Spindle Universal 44mm-63mm With O-ring

Turn/Pull complete

729 Pull handle

Escutcheon 58mm Euro

729, 90x282 Radius Back plate

3x25x79mm Turn/Pull support plate

Fixings Included

⁵/⁸”

Machine

Screws

90

PR⁴-⁵⁸E

Euro Profile

Escutcheon

PR⁴-⁷2⁹

Anti-ligature

Pull Handle

PR6130RBD

Roller Bolt Dead lock

PR4-58E

Euro Profile Escutcheon

PR7101-TPSP

Turn/Pull Support Plate

103

80

3

63

72

14

10

60.5

33

35

68

15

58.5

10

25

235

165

30

16

Note:

The cylinder cut out is made on the external side of the door only and must not go right through the door.

79

25

32

58

10

48.50

25°

102

35

3

PR4-728TP

Anti-ligature Turn/Pull

Model Spindle Length Calculation

46

Door Thickness ÷ 2 + 20mm

+3mm

56

Door Thi 11mm

+3mm

66

Door Thickness ÷ 2 + 20mm

+3mm

76

N/A

N/A

86

N/A

N/A

96

N/A

N/A

Note A :

Check exact door thickness of each door

Note B :

Turn/Pull support plate must not be recessed

deeper than the surface of the door.

PR1 Variant

Addition for

Turn/Pull

Repair Plate

46

Door Thickness Less 3mm

56

Door Thickness Less 3mm

66

Door Thickness Less 3mm

76

N/A

86

N/A

96

N/A

If Fitting

Turn/Pull

Repair Plate

Screw Length

= Door

Thickness

Turn/Pull Screw Length

PR4-729A

Anti-ligature Pull Handle

3

32

25

282

175

90

22.5

36

M5 Bolt

from the

other side

of the door

A: This Turn/Pull is equipped with a screw to adjust the projection of the

spindle if required (most likely if the spindle is cut too short in error) see

drawing A

B: When cutting the spindle to the required length, please make sure that

the material is cut from the end marked B as illustrated. The 3 slots at

the opposite end of the spindle C are an important safety feature and

designed to sheer at 50NM to protect the lock and ensure clinical staff

maintain control of the lock at all times. The O-ring in the first slot will

also assist in the retention of the spindle in the nozzle of the Turn/Pull

during normal use.

There must be at least I sheer

point between the end of the

Turn/Pull nozzle & the lockcase.

Important Spindle & Turn/Pull Information

SOP137 Revision (2)

Sheer Points

Do Not Cut Here

O-Ring

Lockcase

Lockcase

Door

A

B

C

Adjust the spindle projection screw

by inserting screwdriver through

the door/lockcase.

The spindle must

engage in the socket

by at least 7mm

Adjust length of spindle by cutting with a

hacksaw at this end. It is important that

the end of the spindle is cut square.

Primer

a Limited, Unit 8 Bankfield House, 250 Bristol

Av

enue, Blackpool, FY2 0JF

t

0330 058 0988

e

sales@safehingeprimera.com

w

www

.safehingeprimera.com

Important Note: products are protected by Intellectual Property Rights including UK and Community Unregistered Design Rights, UK and Community Registered Designs and UK Patents and Patent Applications.

For further details please contact Safehinge Primera Limited.