PT-5201A/B MINI GRINDER

USER’S MANUAL

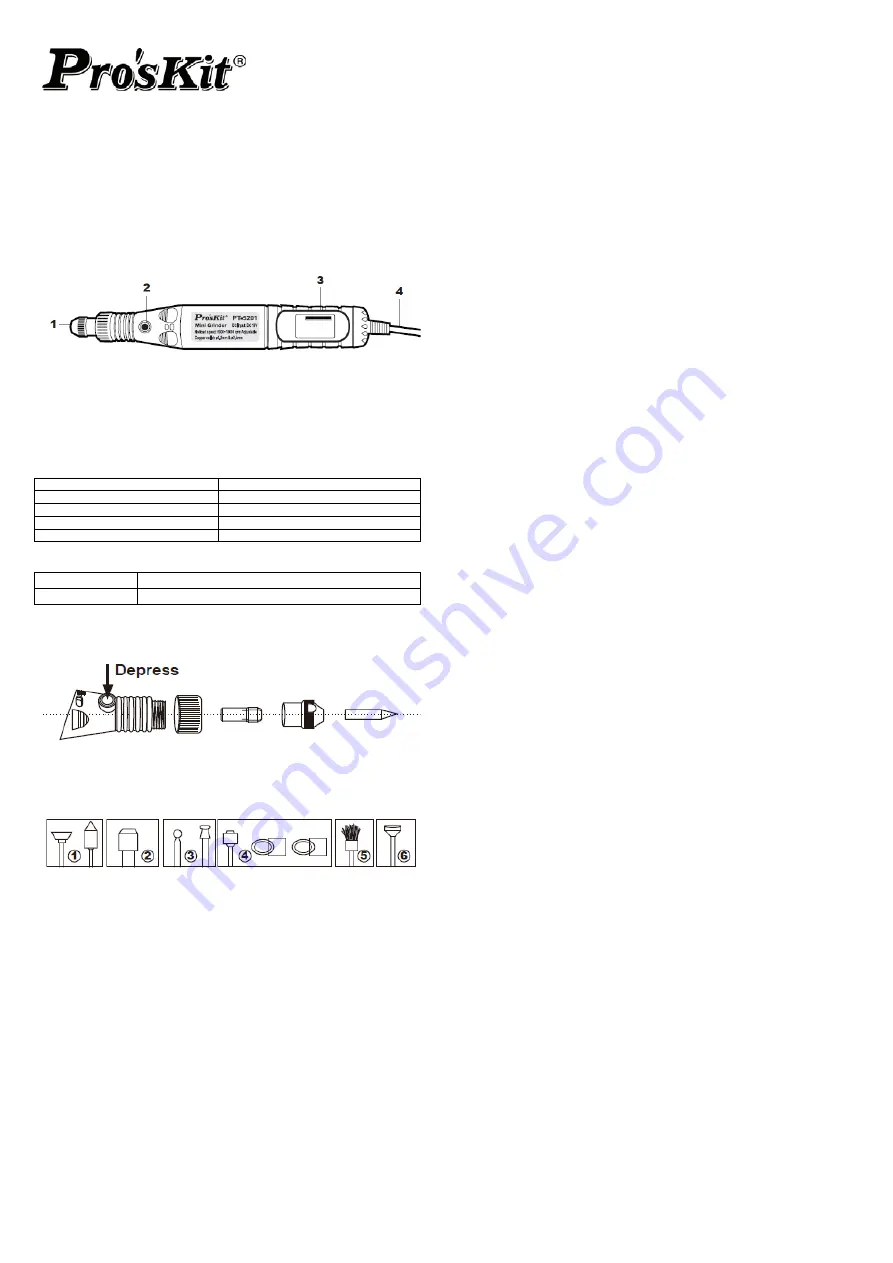

Component

1. Collet nut

2. Spindle lock button

3. Switch

4. Cord

Important!

Please carefully read the instruction in this manual as well as the general.

Safety instruction before using this appliance, keep these manuals

handy.

THE VARIOUS PLASTIC BAGS SHOULD NOT BE LEFT WITHIN THE

REACH OF CHILDREN, RISK OF SUFFOCATION.

Technical characteristics

Voltage 18VDC

Max. diameter

3.2mm

No load speed

8000~18000rpm

± 10%

Vibration level

Less than 0.15mm

Acoustic pressure less than

70dB

Adaptor

Input

230V~50Hz or 120V 60Hz

Output 18VDC

400mA

Use

To use the different accessories, press the shaft locking button located to

the rear of chuck, unscrew it by hand, fit the chosen accessories and

hand tighten the chuck again.

Accessories

(1) 2 pcs grinding (3mm) stones (2) 1 pc collet (ø2.4mm) (3) 2 pcs

diamond bits (5mm)

④

2 pcs sanding bands 6.5x13mm (5) 1 pc nylon bruch (5mm) (6) 1 pc

engraving bit

SAFETY INSTRUCTIONS

IMPORTANT! WHEN USING ELECTRICAL TOOLS, THE FOLLOWING

SAFETY INSTRUCTIONS SHOULD BE OBSERVED TO PREVENT

THE RISK OF ELECTRIC SHOCK, PERSONAL INJURY AND FIRE.

READ AND OBSERVE THESE INSTRUCTIONS CAREFULLY

BEFORE USING THE TOOL.

1.

Keep work area clean

Cluttered and benches invite injuries.

2.

Consider work area environment

Do not expose power tools to

rain. Do not use power tools in damp or wet locations. Keep work

area well lit. Do not use power tools near flammable liquids or

gases.

3.

Guard against electric shock

Prevent body contact with

grounded surfaces(e.g. pipes, radiators, ranges, refrigerators,

etc.).

4.

Keep children away

Do not let visitors contact tool or extension

cord. All visitors should be kept away from work area.

5.

Store ideal tools

When not in use, tools should be stores in a dry,

high, or locked-up place, out of the reach of children.

6.

Do not force tool

It will do a better job and operate more safely at

the rate for which it was intended.

7.

Use right tool

Do not force small tools or attachments to do the job

of a heavy duty tool. Do not use tools for other than their intended

purpose; for example, do not use a circular saw for cutting tree

limbs or logs.

8. Dress

properly

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and non-skid footwear is

recommended when working outdoor. Wear protective hair

covering to contain hair.

9. Use

safety

glasses

Also use a dust mask during pulverulent

operations and wear ear protection. If the noise level. Exceeds

70dB(A), ear protection is obligatory. Indicated noise levels may be

exceeded dependent on the working environment and the material

to be treated.

10.

Use dust extraction

If dust extraction and collection devices are

present on the tool, make sure that they will be used properly.

11.

Do not abuse cord

Never carry tool by cord or yank it to

disconnect it from wall outlet. Keep cord from heat, oil and sharp

edges.

12. Secure

work

Use clamps or a vise to hold the workpiece. It is safer

and it frees both hands to operate tool.

13. Do

not

overreach

Keep proper footing and balance at all times.

14.

Maintain tools with care

Keep tools sharp and clean for better

and safe performance. Follow instructions for lubricating and

changing accessories. Inspect tool periodically and, if damaged,

have them repaired by an authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

Handles dry, clean and free from oil and grease.

15. Disconnect

tools

Disconnect tools when not in use, before

servicing, and when changing accessories such as blades, bits and

cutters.

16.

Remove adjusting keys and wrenches

From the habit of

checking to see that keys and adjusting wrenches are removed

from tool before switching it on.

17. Avoid

unintentional

starting

Do not carry plugged-in tools with

finger on switch. Be sure the tool is switched off before plugging in.

18.

Outdoor use extension cords

When tool is used outdoors, use

only extension cords intended for use outdoors and so marked.

19. Stay

alert

Watch what you are doing. Use common sense. Do not

operate tool when you are tired.

20. Check

damaged

parts

Before further use of the tool, a guard or

other part that is damaged should be carefully checked to

determine that will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or re placed by an authorized service

center unless otherwise indicated elsewhere in the instruction

manual. Do not use tool if switch does not turn it on and off.

21. Warning

The use of any other accessories or attachment other

than recommended in the instruction manual may present a risk of

personal injury.

22.

Have your tool repaired by an expert

This electric appliance is

built accordance with the relevant safety rules. Repair of electric

appliances must only be carried out by experts otherwise it may

cause considerable danger for the user.

23.

Store these instructions for future reference.

Assembly and operation

Mounting an accessory

Keep the spindle lock button depressed. Slacken the collect nut. Insert

the shaft of the accessory into the collet.tighten the collet nut. Release

the spindle lock button in order to remove the accessory, proceed in

reverse order.

Replacing the collet

Keep the spindle lock button depressed. Slacken the collet nut. Remove

the collet nut and the old collet. Place the new collet in. Replace the collet

nut and tighten the collet nut. Release the spindle lock button.

CAUTION!

Always Unplug from the tool and switch off before replacing

the collet; Choose a low speed at first for working.; Never press the

locking pin while the machine is running

Polishing.

A polishing wheel is set for polishing metal and plastic

workpieces. A mandrel is used for mounting a polishing wheel. Place the

mandrel in the collet nut Place a polishing wheel on the screw.

Rouging.

A router bit is used for grooving and for routing figures in plastic,

wooden and metal workpieces. Place a router bit in the collet nut.

Grinding and sanding.

A grinding stone in used for grinding metal,

plastic, wooden and the stone workpieces, A sanding band is used for

sanding wooden and plastic workpieces. Place a grinding stone or

sanding band with mandrel in the collet nut. A sanding band must be

replaced when showing signs of wear Remove the old sanding band from

the mandrel. Place the new sanding band on the mandrel

Clamp all tolls as short as possible, Shafts, which stick out too far will

easily bend causing the machine to vibrate.

Maintenance

CAUTION:

Pull out the plug before maintenance

Keep the machine clean

Keep the air vent unimpeded

Do not use the sharp material to clean the machine

Do not let liquid enter into the machine to prevent it from rust

HAVE YOUR POWER TOOL SERVICED BY A QUALIFIED REPAIR

PERSON USING ONLY IDENTICAL REPLACEMENT PARTS. THIS

WILL ENSURE THAT

THE SAFETY OF THE POWER TOOL IS MAINTAINED.