P U M P D E S I G N A T I O N S Y S T E M

C A U T I O N S & W A R N I N G S

B A S I C T R O U B L E S H O O T I N G

S U G G E S T E D I N S T A L L A T I O N

VELOCITY PLASTIC PUMP

Engineering

Operation &

Maintenance

PUMP TEMPERATURE LIMITS:

PVDF and Polypropylene

4°C – 79°C

(40°F - 175°F)

CAUTION: Maximum temperature limits are based upon mechanical

stress only. Certain chemicals will signifi cantly reduce maximum

safe operating temperatures. Consult Chemical Resistance Guide for

chemical compatibility and temperature limits.

CAUTION: Do not exceed 6.9 bar (100 psig) air supply pressure.

CAUTION: Verify the chemical compatibility of the process and cleaning

fl uid to the pump’s component materials in the Wilden Chemical

Resistance Guide.

CAUTION: Plastic series pumps are made from plastic that is not UV-

stabilized. Direct sunlight exposure for prolonged periods can cause

deterioration of plastic.

CAUTION: V2550 pumps are not submersible.

CAUTION: Always wear safety glasses when operating pump. If

diaphragm rupture occurs, fl uid being pumped may be forced out air

exhaust.

WARNING: Before any maintenance or repair is attempted, the

compressed air line to the pump should be disconnected and all air

pressure allowed to bleed from the pump.

WARNING: Ensure that the air supply line is clear of debris. Use of a 5µ

(micron) in-line air fi lter is recommended.

LEGEND

V2550 / XXXXX / XXX / XX /XXX/

XXXX

O-RINGS

VALVE SEAT

MODEL

VALVE BALLS

DIAPHRAGMS

WETTED PARTS &

OUTER PISTON

AIR VALVE

CENTER SECTION

SPECIALTY

CODE

(if applicable)

V 2 5 5 0 P E R F O R M A N C E C U R V E

V 2 5 5 0 D R Y S U C T I O N - L I F T C U R V E

A 2 5 5 0 V 7 0 / 3 0 O P E R A T I N G C O N D I T I O N

A 2 5 5 0 V P E R F O R M A N C E C U R V E

Pump will not run or runs slowly:

1. Ensure the air inlet pressure is 0.3 bar (5 psig) above the start-up pressure of

the pump.

2. Ensure the differential pressure (difference between the air inlet pressure and

fl uid discharge pressure) is not less than 0.7 bar (10 psig).

3.

Check air line/fi lter for blockage/debris. Check for obstruction in the air

passageways of the pump.

4. Check for objects in the pump that would obstruct the movement of internal parts.

5. Check for severe air leakage (blow-by) coming from the air exhaust. This could

indicate a failed O-ring seal or worn air valve assembly.

6. Inspect for check valve failure. A worn check ball can get stuck in the seat. A check

ball can swell and become stuck if not compatible with fl uid pumped. Replace if

necessary.

Pump runs but little or no product fl ows:

1. Check for cavitation. Confi rm vacuum required to lift the fl uid is not greater than

the vapor pressure of the fl uid being pumped. Slow pump speed to allow viscous

fl uids to fl ow into liquid chambers.

2. Ensure that the suction lift requirement is within the pump model’s capability.

3. Inspect for check valve failure. A worn check ball can get stuck in the seat. A check

ball can swell and become stuck if not compatible with fl uid pumped. Replace if

necessary.

Air bubbles in pump discharge:

1. Check for ruptured diaphragm.

2. Check tightness of outer piston to shaft.

3. Check integrity of O-ring seals, especially intake side of manifold.

4. Ensure pipe connections are airtight.

Product comes out of air exhaust:

1. Check for ruptured diaphragm.

2. Check tightness of outer piston to shaft.

PUMP SELECTION:

Ensure that the pump materials of construction are compatible with

the pumping media and the immediate surroundings the pump will be subjected to. Refer to the

Wilden Chemical Resistance Guide. For optimum life and performance, the pump size should be

specifi ed so that daily operation parameters are not near the pump’s maximum rated performance

capabilities.

INSTALLATION:

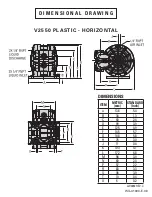

The Velocity pump has two foot-mount confi gurations and can be mounted

in any orientation. The pump can be mounted in place or left free standing for use in multiple

locations. If the pump is to be mounted in place, it is suggested to attach the Base Assembly to

the desired horizontal or vertical surface using four (4) screws (not supplied) and then attach the

pump to the Base Assembly (See Assembly Instructions).

The Velocity pump has two inlet fl uid connections and two discharge fl uid connections. One inlet

and discharge connection must be plugged using the supplied NPT plugs.

PIPING:

The suction and discharge piping diameter should be equivalent or larger than the

diameter of pump connection, the length and complexity of the suction and discharge piping

should be minimized, unnecessary elbows, bends and fi ttings should be avoided, all in an effort

to reduce friction losses.

The suction hose must be non-collapsible. If rigid piping is used, it should be supported

independently of the pump. In addition, the piping should be aligned to avoid placing stress on

the pump fi ttings.

When used in self-priming applications, it is critical that all fi ttings and connections are airtight or

a reduction or loss of pump suction capability will result. Ensure that the suction lift requirement

is within the pump model’s capability.

AIR SUPPLY:

Every pump should have an airline large enough to supply the volume of air

necessary to achieve the desired pumping rate. Air pressure to the pump should not exceed a

maximum of 6.9 bar (100 psig). For best results, the pumps should use a 5µ (micron) air fi lter to

eliminate air-line contaminants, a needle valve and pressure regulator.

SOLENOID CONTROL:

When start-stop operation of a standard air valve equipped pump is

controlled by a solenoid valve in the air line, a three-way (3/2) solenoid valve should be used to

vent pressurized air between the solenoid and pump when the pump is stopped.

PUMP OPERATION:

Once installation is complete, pump operation can be started by opening

the air shut-off valve (do not exceed the pump’s maximum rated pressure). The pressure regulator

and needle valve are used to adjust the speed of the pump.

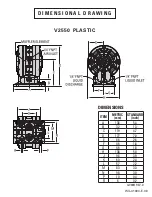

Ship Weight .........................2 kg (4 lb)

Air Inlet ........................... 6 mm (1/4”)

Inlet .................................. 6 mm (1/4”)

Outlet ............................... 6 mm (1/4”)

Suction Lift ...............4.3 m Dry (14.2’)

6.2 m Wet (20.4’)

Disp. per Stroke

1

....... 0.04 L (0.01 gal)

Max. Flow Rate ....21.6 lpm (5.7 gpm)

Max. Size Solids ......... 0.8 mm (1/32”)

1

Displacement per stroke was

calculated at 4.8 bar (70 psig) air inlet

pressure against a 2.1 bar (30 psig)

head pressure.

Example: To pump 12.5 lpm (3.3 gpm)

against a discharge head of 2.1 bar

(30 psig) requires 4.1 bar (60 psig) and

10.4 Nm

3

/h (6.1 scfm) air consumption.

Caution: Do not exceed 6.9 bar (100

psig) air supply pressure.

Suction-lift curves are created

using pumps operating at 305 m

(1000’) above sea level. This chart is

meant to be a guide only. There are

many variables which can affect the

pump’s operating characteristics.

Suction lift can be affected by

the number of intake/discharge

elbows, viscosity of pumping fl uid,

elevation (atmospheric pressure),

pipe friction losses and other

factors.

Caution: Do not exceed 6.9 bar (100

psig) air supply pressure.

DIAPHRAGMS

TSS = FULL-STROKE PTFE W/ SANIFLEX

BACK-UP O-RING

ZWS = WIL-FLEX™ [Santoprene

®

(Three Black Dots)]

VALVE BALLS

TF = PTFE (White)

WF = WIL-FLEX™ [Santoprene

®

(Three Black Dots)]

VALVE SEAT

K = KYNAR

P = POLYPROPYLENE

VALVE SEAT O-RING

TV = PTFE-ENCAP. FKM

WF = WIL-FLEX (Santoprene

®

)

SPECIALTY CODES

0150 Accu-Flo, 24V DC Coil

0151 Accu-Flo, 24V AC/12V Coil

0155 Accu-Flo, 110V AC Coil

MODEL

V2550 = 6 mm (1/4”) VELOCITY

A2550V = 6 mm (1/4”) ACCU-FLO™

WETTED PARTS & OUTER PISTON

KK = PVDF / PVDF

PP = POLYPROPYLENE / POLYPROPYLENE

AIR CHAMBER / CENTER BLOCK

PP = POLYPROPYLENE

AIR VALVE

A = ALUMINUM (ACCU-FLO Only)

E = PET

MATERIAL CODES

This curve demonstrates the fl ow created when the stroke rate is varied

under static air and fl uid pressure conditions. This curve can be applied

to different pressure conditions to estimate the change in fl ow due to

stroke rate.

5

[8]

4

[7]

3

[5]

.30+ .25

KEY

.20 .15

2

[3]

1

[2]

1 2 3 4

[4] [8] [11] [15]

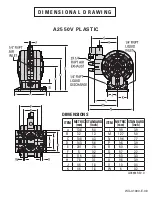

Ship Weight .........................2 kg (4 lb)

Air Inlet ........................... 6 mm (1/4”)

Inlet .................................. 6 mm (1/4”)

Outlet ............................... 6 mm (1/4”)

Suction Lift ...............4.3 m Dry (14.2’)

6.2 m Wet (20.4’)

Disp. per Stroke

1

....... 0.04 L (0.01 gal)

Max. Flow Rate ....14.8 lpm (3.9 gpm)

Max. Size Solids ......... 0.8 mm (1/32”)

1

Displacement per stroke was

calculated at 4.8 bar (70 psig) air inlet

pressure against a 2.1 bar (30 psig)

head pressure.

Example: To pump 7.9 lpm (2.1 gpm)

against a discharge head of 2.1 bar (30

psig) requires 4.1 bar (60 psig) and 6.6

Nm

3

/h (3.9 scfm) air consumption.

Caution: Do not exceed 6.9 bar (100

psig) air supply pressure.

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06

WIL-41000-E-06