Manual

AS N-12-R

AS N-12-R

OPERATING INSTRUCTIONS

HAND TOOL FOR BLIND RIVET NUT M5-M12

4

6

7

5

2

3

8

1

9

TECHNICAL INFORMATION

Capacity:

Blind rivet nuts M5–M6–M8–M10 –M12

Material:

Aluminium, Steel and Stainless Steel

Size:

210 (L) x 180 (H) x 40 (P) mm

Weight:

1,82 kg

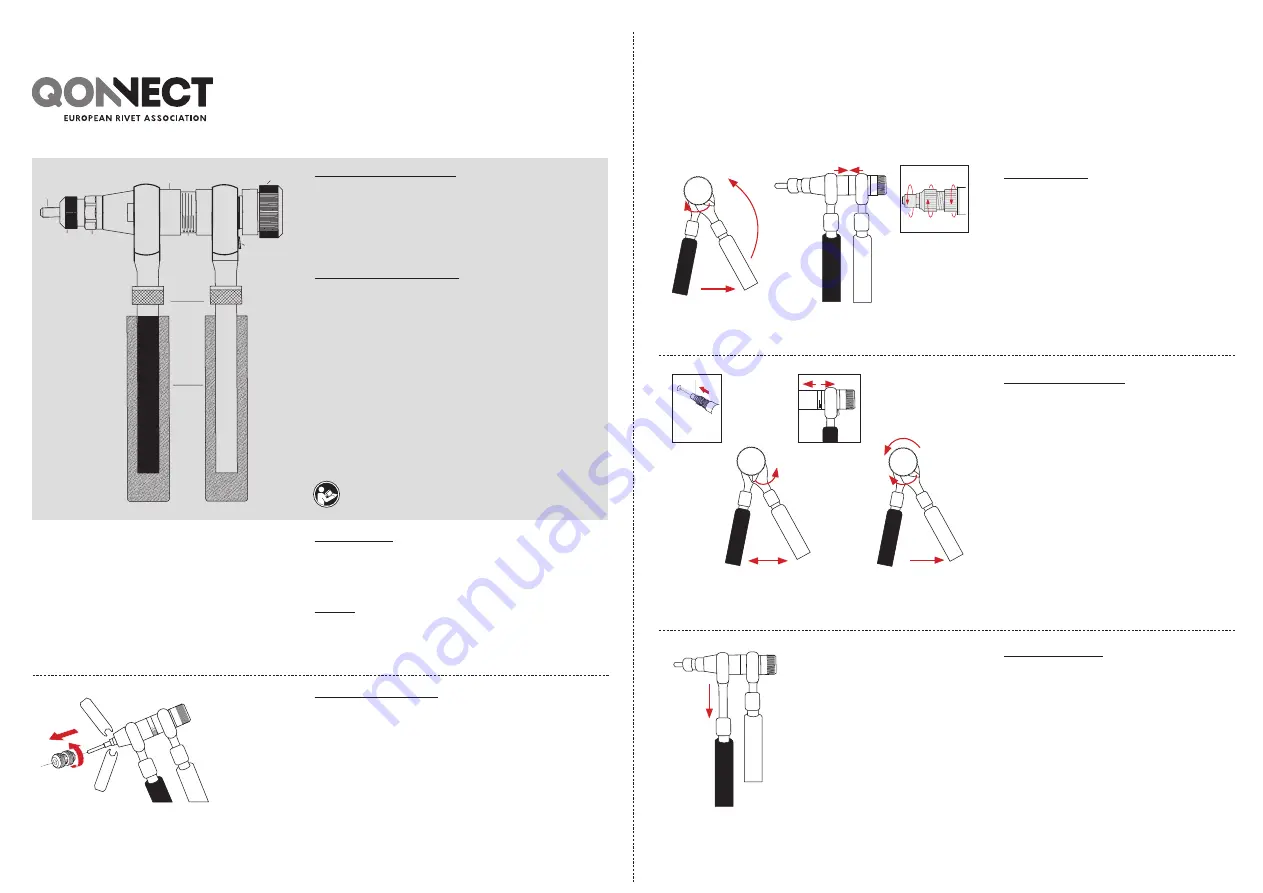

DESCRIPTION OF THE TOOL

1. Tool body

2. Front and back lever

3. Turning knob

4. Mandrel M12

5. Anvil M12

6. Counter lock nut

7. Stroke indicator

8. Ratchet switch

9. Lever extension system

Read the manua

l

INSTRUCTIONS

The hand tool will be standard equipped with the M12 anvil and

M12 mandrel. The other components will be stored separate in the

carton box.

FIRST USE:

Make sure before using the tool that the anvil and mandrel are

suitable for the thread of the insert to be used. Otherwise change

to a different size.

CHANGE TO A DIFFERENT SIZE:

Unscrew the anvil (5) and the lock nut (6). Use the two spanners

in the carton box to unscrew the mandrel (4). Please note that the

mandrels have

left-handed thread

. To unscrew turn the mandrel

clockwise. Replace it by choosing the correct size from the spare

parts in the carton box and turn counter clockwise to fasten.

A

ANVIL ADJUSTMENT:

After changing to a different size at A, it is necessary to adjust

the anvil (5) and its counter lock nut (6). Put the tool in its

starting position by pushing the ratchet switch (8) to the left

and turn the back lever (2) counterclock wise until the stroke

indicator (7) is invisible. The tool body is now in starting

position. The protrusion of the mandrel out of the anvil must

be as long as the whole rivet nut. Unscrewing the counter lock

nut (6) to adjust the anvil (5) by turning left or right, to

increase or decrease the length. After the correct length is

applied, screw the counter lock nut until it is tight.

B

SETTING A THREADED INSERT:

Put the tool in start position by pushing the ratchet switch

(8) to the left and turn the back lever (2) counterclock wise

until the stroke indicator is invisible. Screw the insert on

(relate about 2 mm distance between front and back part of

the body) the threaded end of the mandrel and insert it into

the hole of the material. The hole size must be slightly larger

than the rivet nut, check the drill specifications of the rivet

nut. Push the ratchet switch (8) to the right and open the

levers (2) for one third till you hear the ratching sound of the

mechanism, then close the levers completely. Repeat these

steps to clamp the rivet nut into the material tightly. The tool

body is now extended and the stroke indicator (7) visible for

checking the correct stroke. After the rivet nut is set, push the

ratchet switch (8) to the left and turn the back lever (2) one

time counter clockwise, this will release the threaded insert.

Unscrew the insert, by using the turning knob (3) on the back

of the tool.

C

EXTENDING THE LEVERS:

When working with (stainless) steel threaded inserts the

workingload of the tool can be lowered by extending the

levers. The extended levers creates a bigger power ratio and

makes it much lighter to clamp the stronger material threaded

inserts. Push the lever extension system (9) down to unlock

and slide the lever down till the right position. In case of a

small and narrow working area you can choose to extend only

the front or back lever.

Note: The levers can get stuck when too much force or

speed is applied during extension of the levers.

D

7

8

2

5 6

7

8

2

8

2

3

9